Specification

| Electrical parameters |

| Maximum operating voltage (kV) |

126 |

| Impact withstand voltage (kV) |

550 |

| Creep distance (mm) |

4150 |

| Creepage distance ratio (mm/kV) |

>31 |

| Mechanical parameters |

| Maximum cable cross-sectional area (mm²) |

1600 |

| Maximum insulation outer diameter (mm) |

91 |

| Approximate total weight (kg) |

60 |

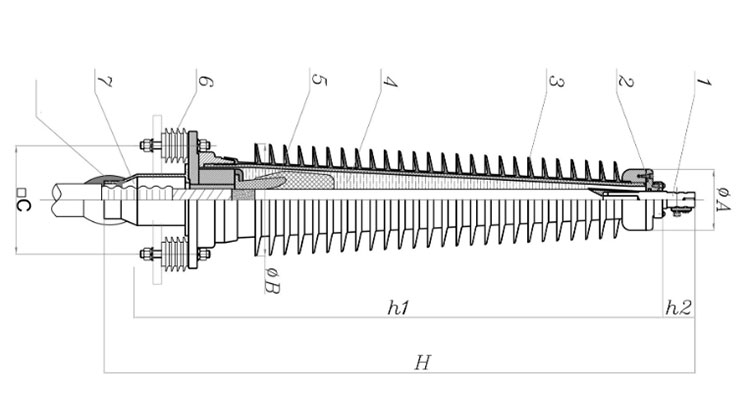

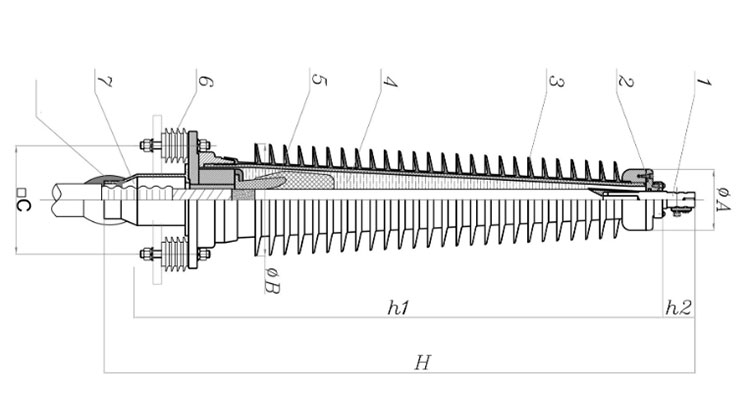

| Main dimensions |

| φA (mm) |

180 |

| φB (mm) |

328 |

| □C (mm) |

318 |

| H (mm) |

1728 |

| h1 (mm) |

1478 |

| h2 (mm) |

82 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is Composite Cable Bushing?

Composite Cable Bushing is a specialized component, which insulates and protects cables as they go through grounded enclosures in high-voltage systems. This is a product made from composite materials, typically silicone rubber, fiberglass, or epoxy resin, offering a durable and weather-resistant interface and is used in such an environment to give high-performance insulation. Composite materials offer great weathering, UV protection, and environmental contaminant resistance which helps reduce maintenance and extend the life of the bushing. It is designed for use in applications where reliability and compactness are important; it can operate in many climates and demanding conditions to provide stability and electrical isolation between conductive parts. Its high dielectric strength helps to maintain safe, uninterrupted power transmission, and because of reduced overall weight and simplicity of handling and installation, it reduces the overall weight. Especially in high voltage environments where insulation integrity is very important, it is usually designed with stress relief shapes and contours of surfaces designed to help prevent surface discharges and readily distribute electric fields.

Features

- Distinct Tapered Shed Structure:

A specialized tower-shaped shed structure is designed into the bushing to enhance overall stability and better performance in high-voltage applications.

- Uniform Shed Coverage on High Electric Field Zones:

Motivated to reduce the surface discharges and to improve the insulation integrity, we strategically distribute the sheds over the areas with the highest electric field intensity on the outer insulation.

- Dual-Metal Structure on Rubber Termination Ends:

The rubber ends of the rubber components are designed with a double metal design attached, which will offer a more reliable shield and seal, as well as a more durable and resistive termination of environmental factors.

Main Components

- Connection Terminal:

The cable sealing bushing assembly is facilitated by this terminal for secure electrical connections during current transfer, thus providing reliability.

- Grading Shield:

The grading shield, or corona shield, is used to distribute this electric field evenly, to lower stress, and to avoid corona discharge in areas with high voltages.

- Composite Insulation Bushing:

It’s a sleeve made from composite materials that function as primary insulation, protecting it from external contaminants and environmental factors.

- Stress Cone:

The stress cone is intended to reduce the electrical stress at the bushing termination point and to provide an even distribution of electrical stress to increase insulation effectiveness and longevity.

- Insulating Filler:

The insulation also stops moisture from getting in, this fills up the internal spaces.

- Support Insulator:

This component supports the bushing structure with mechanical stability and keeps the assembly at zero alignment.

- Sealing Tail Tube:

The sealing tail tube that is located at the end of the bushing is a moisture-resistant seal, which prevents leaks and provides long-term insulation reliability.

Certificate

Factory

Hot Tags: Composite Cable Bushing, Cable Accessories, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage