Introduction

Our company has been specialized in producing insulators for drop-out fuses for many years and has rich production experience. Our products have passed relevant tests in strict accordance with the standard IEEE C37.41, and the main market for our products is the United States.

Problem description

Traditional drop-out fuse insulators have deficiencies in mechanical properties, durability, and insulation performance, and it is difficult to meet the high requirements of modern power systems.

Solutions

1. Composite insulator core rod

We use the core rods of our brother company Tapuri Electric (the core rod manufacturer recommended by State Grid UHV); the core rods strictly implement relevant standards such as IEC 61109-2008, ANSI C29.13-2012, and GB/T 19519-2014.

1.1 Material selection

High-strength alkali-free and acid-resistant glass fiber: ensure the stability and reliability of the composite insulator core rod under long-term AC/DC voltage operation.

ECR acid-resistant and high-temperature-resistant core rod: The fiber adopts acid-resistant glass fiber and alkali-free, brittle-resistant, fluorine-free, and boron-free fiber with better electrical performance.

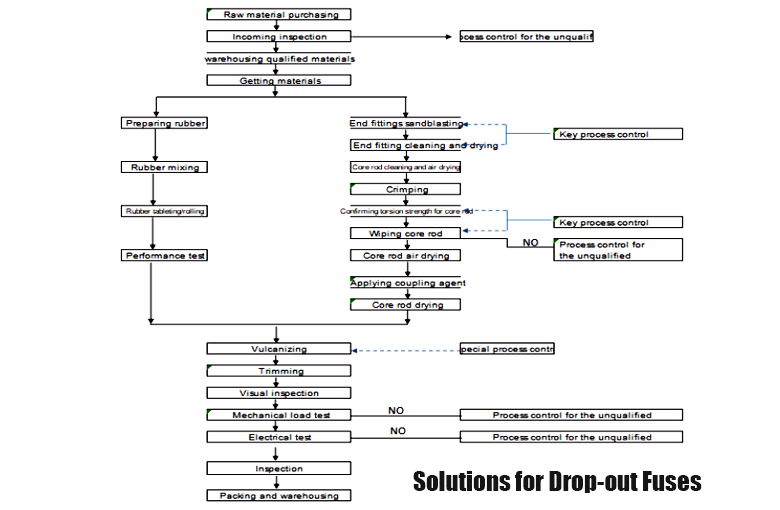

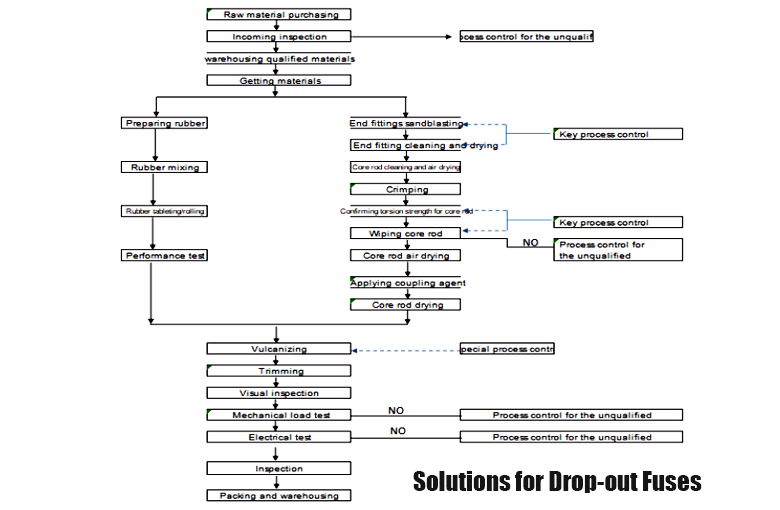

1.2 Production process

Vacuum impregnation process: The electrical insulation performance of the core rod reaches 40kV/cm (national standard 30kV/cm).

Mold release agent-free core rod: Ensure the best bonding performance between the core rod and the silicone rubber sheath interface.

1.3 Certification and testing

7200h stress corrosion resistance test: Passed the test of Wuhan High Voltage Research Institute of State Grid Corporation and obtained the test report.

2. External insulation silicone rubber

We have done a lot of optimization and improvement work on the external insulation shed sheath of composite insulators and used it in production.

2.1 Material optimization

Improved silicone rubber formula: Make its performance more excellent.

2.2 Certification and testing

1000h aging test: According to the relevant requirements of IEC 61109-2008 and GB/T 19519-2014, it passed the test of the Power Industry Power Equipment and Instrument Quality Inspection and Testing Center.

5000h aging test: According to the relevant requirements of IEC 62217-2012 and GB/T 22079-2008, it has passed the test of the Power Equipment and Instrument Quality Inspection and Testing Center of the Power Industry.

3. Hardware Process

Forging process: Both the intermediate hardware and the end hardware adopt the forging process. Compared with conventional casting hardware, the mechanical properties are more stable, and internal casting defects and invisible cracks are avoided.

Verification solutions

Wishpower uses professional tests and experiments to check the mechanical strength and connection stability of insulators; test durability and insulation performance; and conduct long-term aging and environmental adaptability tests. Ensure that the product solution is complete.

Additional information

Wishpower provides more technical data and product information.

User manuals and technical support can be obtained by contacting us.

Conclusion

Insulators for drop-out fuses have excellent performance in improving insulation performance, mechanical strength, and durability, are particularly suitable for the high requirements of modern power systems, and have broad market application prospects. We welcome users to provide feedback and suggestions during use.

Are you also facing trouble? You can get help directly through info@wishpower.net