Specification

| Type of Insulator |

FXBW-500/(420/400) |

FXBW-500/(550/530) |

| Specified Voltage |

500 kV |

500 kV |

| Specified Mechanical Tensile Load |

420/400 kN |

550/530 kN |

| Connection Structure Mark |

28 |

32 |

| Section Length |

4450±50 mm |

4450±50 mm |

| Min. Arcing Distance |

4000 mm |

4000 mm |

| Big shed Diameter |

190 mm |

218 mm |

| Diameter of Grading Ring |

350/370 400 mm |

350/370 400 mm |

| Diameter of Grading Ring |

370/400 mm |

370/400 mm |

| Min. nominal Creepage Distance |

14000 mm |

14000 mm |

| Lightning Impulse Withstand Voltage(peak value) |

≥2250 kV |

≥2250 kV |

| Operating Impulse withstand Voltage(Peak) |

≥1240 kV |

≥1240 kV |

| Power Frequency WithstandVoltage Min.Wet(RMS) |

≥740 kV |

≥740 kV |

| Reference Weight |

33 kg |

34 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

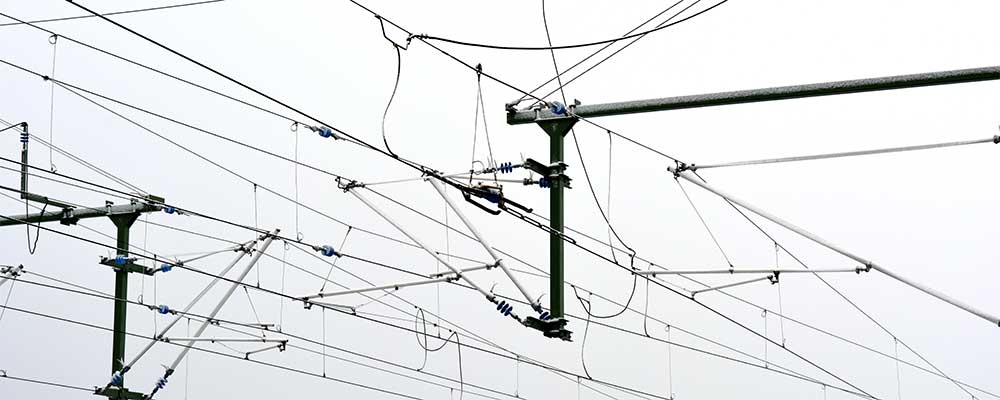

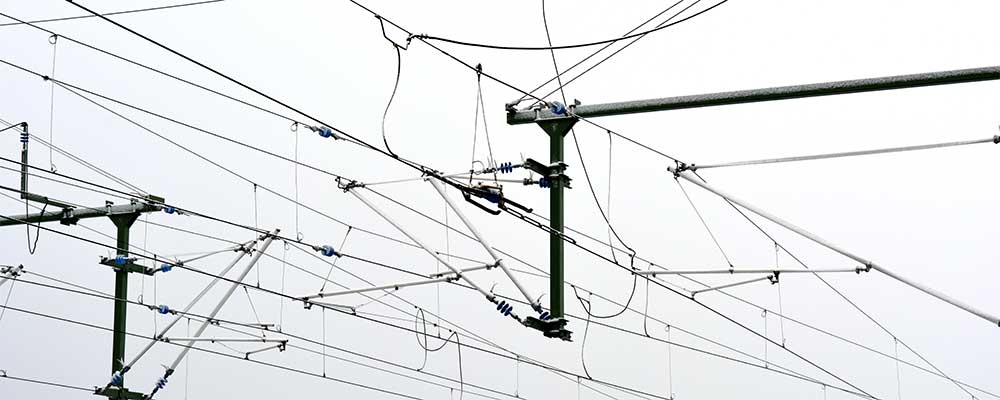

What is Composite Suspension Insulator?

The composite suspension insulator is a specially designed insulator used primarily in high-voltage transmission and distribution systems supporting and electrically isolating overhead conductors hung from towers or poles. The core of this insulator is glass fiber reinforced epoxy resin giving this insulator high mechanical strength and attached to the core is a silicone rubber or similar polymer casing. Due to their flexibility and lightweight, they are prized for their reduced mechanical loads to the supporting structure and ease of installation. This material composition makes it corrosion-resistant, impact-resistant, and environmental aging-resistant which makes them long-lasting for uneven climate from extremely cold to extremely UV exposure. Further, the design curtails maintenance needs and significantly cuts the cost for the application demanding long-term reliability, making composite suspension insulators the preferred choice. Furthermore, their structure also improves resistance to mechanical stresses resulting from wind, ice, or seismic activity, strengthening their contribution to guaranteeing the integrity of transmission networks.

Why is this insulator called “suspension “?

What the term suspension insulator means is that the insulators are suspended from the electrical grid and work that way. The hanging or “suspended” nature of other insulator types means that they can support the weight of overhead conductors (wires) and are electrically isolated from the structure they are attached to. The suspended design offers the insulator a “floating” movement enabling it to “swing” or adapt to mechanical stresses like mechanical stresses of wind, ice load, or thermal expansion of conductors. In addition, multiple units can be strung together in series to increase their flexibility in handling higher voltage demands. Based on the above findings, the ‘suspension’ setup can be used to keep these insulators effectively insulated and offer clearance in dynamic outdoor environments, which is essential to safe and reliable power transmission.

Benefits

A variety of unique advantages exist in polymer suspension insulators which make their use highly recommended for modern power transmission systems. The major advantage is their increased impact resistance which is most beneficial in earthquake areas. Flexible material allows it to absorb and withstand violence moving quickly, reducing the likelihood of damage and increasing grid stability.

An additional plus for them is their low moisture absorption, keeping the aging problems to the outside. However, this feature is critical in humid or coastal environments where traditional insulators can age faster from moisture penetration. Also, composite suspension insulators cause little interference with radio and television and are appropriate for urban areas where radio and television signal interference is possible.

They are also chosen because of their smooth surface finish that prevents dirt buildup and makes cleaning easier – increasing their service life and decreasing the frequency of maintenance in high-pollution areas. They also show improved impact resistance, and therefore are more suitable to withstand events such as bird strikes, or other external forces, maintaining performance in varied environmental conditions.

Application

- Mountain Power Lines:

It is used in mountainous areas to adjust to such challenges as high altitude, rugged terrain, and large fluctuations in temperature. Due to its lightweight structure, transportation, and installation in places with restricted access as well as the capability to survive high UV exposure and mechanical stress.

- Desert Environments:

The good news is that power lines that cross desert areas do well since they are so resistant to dust, sand, and strong sunlight. Its hydrophobic surface repels sand and dust helps prevent the accumulation of pollutants and maintains stable performance under abrasive conditions.

- Wind Farms:

It provides reliable support for power transmission in wind energy facilities where space is sometimes limited and structures are subject to high wind forces. Being flexible and resisting vibration and wind loads, it is suitable for applications as system components of towers on wind turbines.

- High-risk Wildlife Areas:

It helps to more effectively mitigate potential wildlife-related damage in areas of primary wildlife and power line interaction — for example in high bird population areas. Since they are more durable and more resistant to impact from other animals such as birds and so on, failure as a result of a bird strike, or other animal interaction is less likely.

- Remote or rural distribution networks:

Composite suspension-type insulators are used for remote areas where maintenance can be difficult and infrequent. For their low-maintenance design and reliability, these are ideal. They reduce costly or logistically complex visits that are necessary for supplying continuous power over long distances.

Certificate

Factory

Hot Tags: Composite Suspension Insulator, Composite Insulator, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage