Specification

| Type |

FXBW-500/160 |

| Rated voltage(KV) |

500 |

| Specified mechanical load |

160 |

| Section length(mm) |

4080 |

| Min Arc distance(mm) |

3730 |

| Leakage distance (mm) |

12750 |

| Lightning impulse withstand BIL(KV) |

2250 |

| Power frequency withstand(wet) (KV) |

740 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

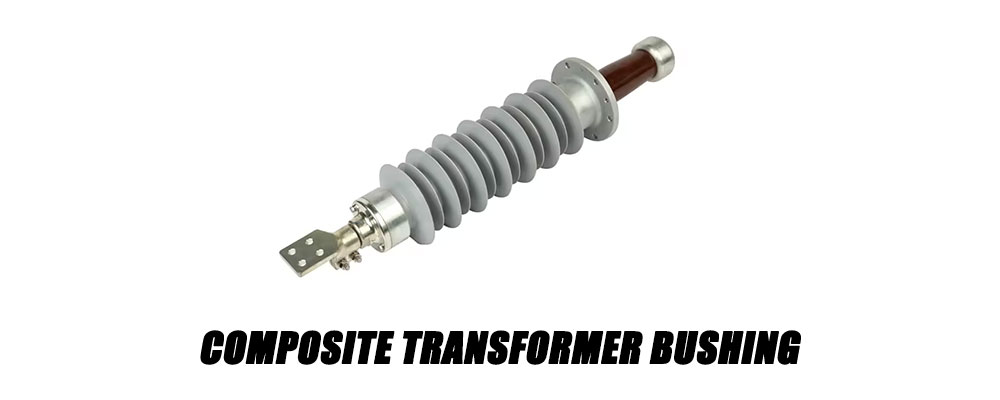

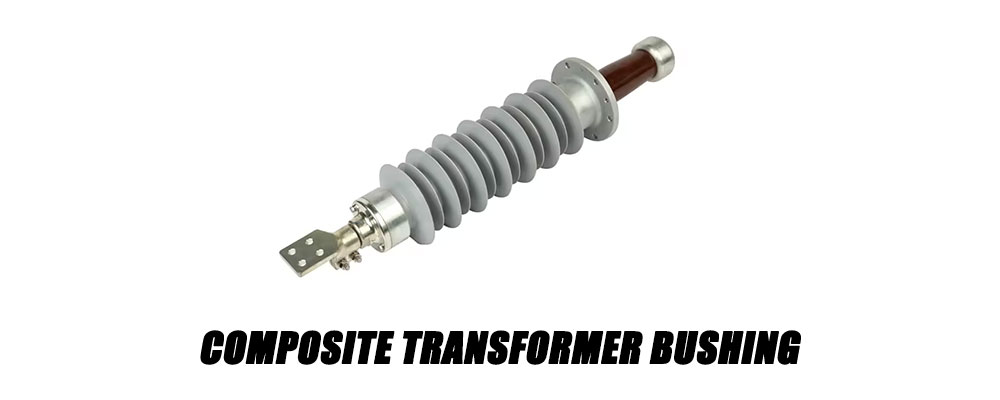

What is Composite Transformer Bushing?

Composite Transformer Bushing is an innovative electrical product intended to allow the electrical conductor to pass through the grounded structure like the casing of a transformer, breakers, and other high-voltage equipment while being insulated. It is not made from porcelain but from a composite structure and is normally made out of a fiberglass epoxy resin core covered with silicone rubber housing. It offers improved mechanical properties with sufficient electrical insulation, and good environmental stability including resistance to Ultraviolet radiation, humidity, and pollution. The specific application used most commonly in composite bushings is the lightweight and compact material, which is easier to handle and install compared to other materials, that take a longer time and amount of money to install and maintain. They show excellent performance quality under adverse environmental factors such as humidity, variation in temperatures as well and pollution and therefore, are very suitable for exposed applications. Second, the silicone rubber has hydrophobic properties as it greatly reduces the chances of flashovers hence improving the reliability and safety of the power system.

Market Trends

This power transformer bushing has stepped by and attracted market interest because of its better performance; however, its domination is yet to be compared to the widely-used porcelain bushings. Analyzing the market characteristics, it can be concluded that the frequency of using composite bushings increases only gradually, which is explainable by the constant demand for efficient and easy-to-service equipment applied in the field of power transmission and distribution. At present, it is mainly used in regions where the environment is extremely tough like coastal regions, areas that have serious pollution, or regions that experience a regularity of earthquakes. In such situations, the advantages of the material which include the ability to resist Moisture, Pollution, and Mechanical shock contribute greatly to its performance.

Benefits

1. Improved mechanical strength and durability:

This transformer bushing is composed of epoxy resin glass fiber and silicone rubber materials that have good mechanical strength. They are more resistant to shock, vibration, and seismic activity to porcelain bushings that are brittle and tend to break,’ in the presence of mechanical stress.

2. Lightweight and easier to handle:

It is lighter in weight, therefore making it easier to transport handle, and install. The weight reduction does not only affect the transportation cost of the product but also results in less time to be spent in the installation process thus cutting on the cost of labor.

3. Enhanced performance in harsh environments:

It features a silicone rubber shed that can resist water hence it does not easily develop flashover due to moisture accumulation. That makes them ideal for areas with high humidity, pollution, or with a salty content in the air, in which porcelain bushings may deteriorate in a shorter period.

4. Reduced maintenance requirements:

Due to its rugged material properties, it generally requires less maintenance. It resists aging, UV radiation, and environmental pollutants, thereby extending its service life and reducing maintenance interventions, which can save costs in the long run.

5. Increased safety and reliability:

Unlike porcelain bushings, which can fail explosively, they typically fail less catastrophically due to their non-brittle nature. This feature improves overall safety by reducing the risk of dangerous fragmentation upon failure.

6. Resistant to pollution and UV degradation:

It is more durable in pollution or ultraviolet radiation, which over time affects the porcelain covering. Its silicone rubber keeps its performance in severe conditions uncompromised which leads to great dependability.

Cost Analysis

However, cost analysis when comparing this terminal bushing in transformer to the traditional porcelain one shall involve short-run and long-run costs. In general, composite bushings are more costly initially and this is due to the more sophisticated materials and techniques that are being employed in the production of these bushings such as a fiberglass and epoxy middle layer and an outer layer of silicone rubber. These advanced materials and technologies also raise the initial expenses for production compared with the comparatively basic and rather established production of porcelain bushings. However, the initial cost might be higher if compared to traditional porcelain but in the case of its total lifecycle costs. It is also quite a pleasant advantage in terms of saving money on maintenance and operational costs. This is because they have better environmental parameters namely, contamination, UV radiation, and mechanical shock which make them require less inspection and maintenance as compared to other types of batteries.

Certificate

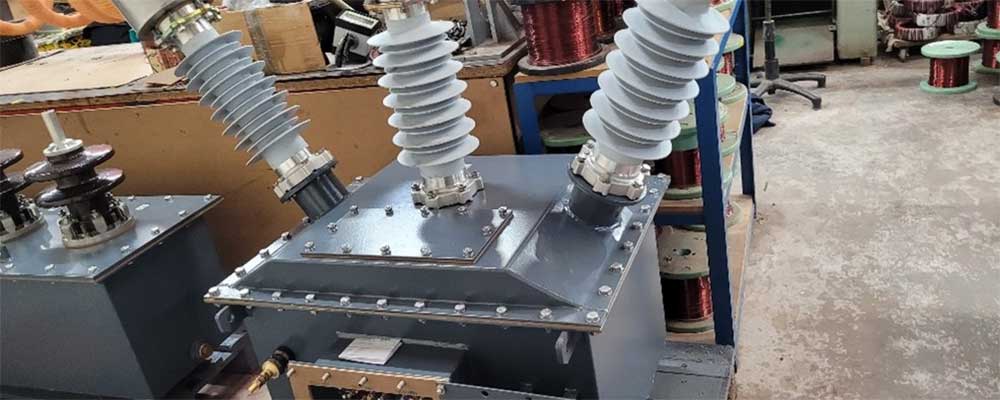

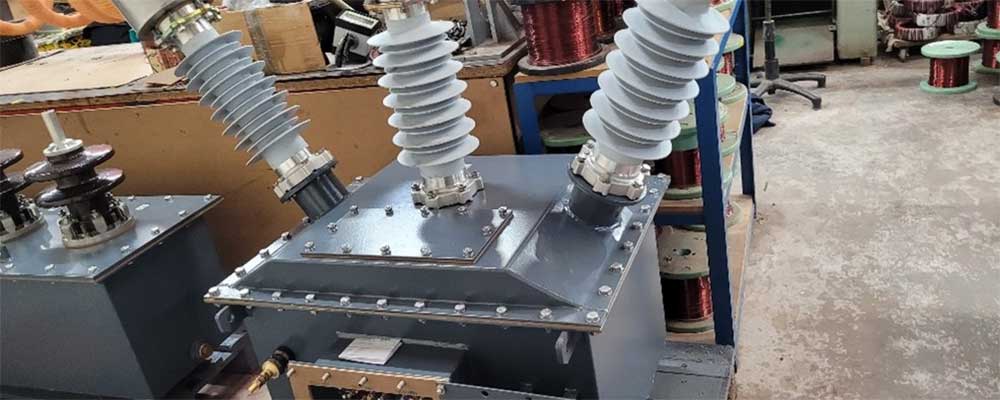

Factory

Hot Tags: Composite Transformer Bushing, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage