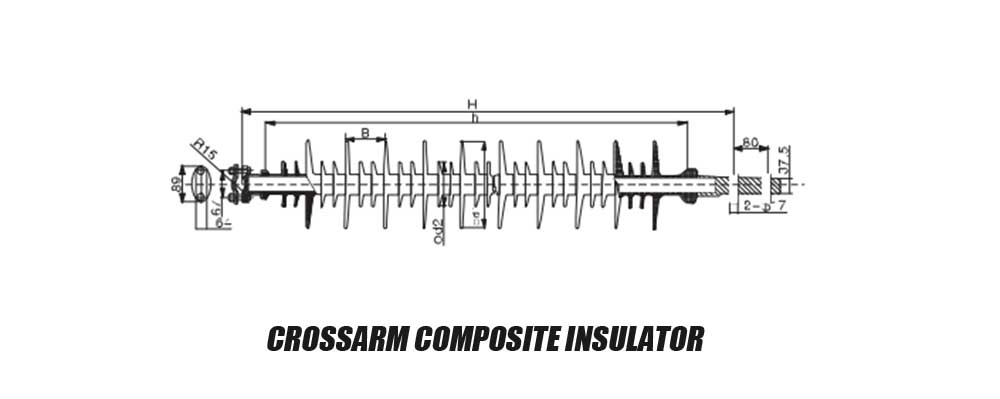

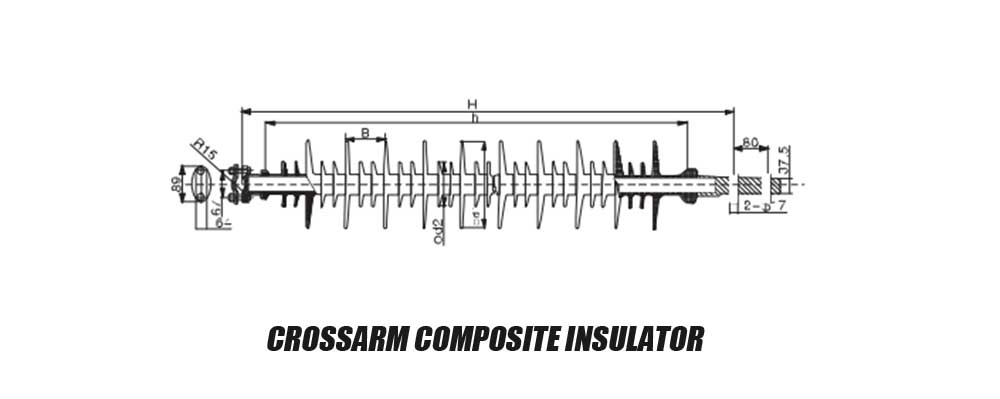

Specification

| Type of Insulator |

FS-220/0.25-MJ-2240 |

FS-220/0.5-MJ-2240 |

| Specified Voltage |

220 kV |

220 kV |

| Specified Mechanical Tensile Load |

0.25 kN |

0.5 kN |

| Section Length |

2240±30 mm |

2240±30 mm |

| Min. Arcing Distance |

2100 mm |

2100 mm |

| Big Shed Diameter |

190 mm |

250 mm |

| Diameter of GraDing Ring |

305 mm |

305 mm |

| Min. Nominal Creepage Distance |

6300 mm |

6300 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

≥1000 kV |

≥1000 kV |

| Power Frequency Withstand Voltage min. wet(RMS) |

≥395 kV |

≥395 kV |

| Reference Weight |

18 kg |

21 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is the Crossarm Composite Insulator?

The cross-arm composite insulator is one of the line insulators used in overhead transmission and distribution networks. It incorporates what has to do with the use of new composite and mechanical structures intended to endure environmental pressures including meteorological force and mechanical force. The middle part or core of the insulator is normally made out of glass fiber-reinforced resin material offering tensile strength as well as electrical insulation. The outer layer is provided as a layer of weather-resistant silicone rubber or polymer to enhance the life of the cover and to reduce the propensity of a flashover. This highly efficient product’s novel features are its lightweight and excellent mechanical performance, which ensures easy installation and long-term use, which is essential in the construction of new power networks. Wishpower has focused on composite insulators for over twenty years and we can offer various kinds of insulators and solutions.

What other line insulators are there?

- Suspension Composite Insulator:

The insulators are widely utilized in such as high voltage transmission lines. These are situated at the tower where they give support and electrical isolation to the conductors. Its composed structure allows for great tensile strength and durability against pollution and harsh climatic conditions such as hurricanes and tornadoes.

- Pin-Type Composite Insulator:

Suspended on or fixed to poles or cross arms or hung from tension bands, pin-type composite insulators both support the conductor and also provide isolation. It has a basic design with a pin fixed on the pole and a composite insulator of high durability and electrical steadiness.

- Long Rod Composite Insulator:

This type is commonly appropriate for high-voltage transmission lines as its slender shape helps minimize the build-up of dust upon them. This one is characterized by high mechanical strength as well as very good resistance to, for example, weathering.

- Line Post Composite Insulator:

These units have been developed for mounting on poles and cross-arms in medium voltage networks to offer mechanical support and electrical insulation. Thanks to them, they can withstand various mechanical loads and, in general, they are manufactured from a composite material, ensuring long-term durability and protection against environmental influences.

Unique features

- Integrated cross-arm design:

Unlike other types of insulators, cross-arm insulator combines the insulator and support in one piece of equipment. One of the designs presented above does not require additional cross-arm, saves material to boot, and is easier to put up.

- Compact and lightweight:

It is small and designed to have a minimal cross-sectional area of the conductor therefore suitable for regions where space on the transmission poles is limiting sometimes or where aesthetics matter. That light weight also helps in less encumbrance on the pole tower.

- Enhanced flexibility:

It offers greater flexibility in alignment and installation than traditional cross-arm and insulator combinations. This flexibility makes field adjustments easier to accommodate a variety of line configurations.

- Improved load distribution:

Its integrated design distributes mechanical loads more evenly throughout the structure. This reduces stress concentrations and improves the overall durability and service life of the insulator.

- Aesthetic integration:

It provides a sleeker, more integrated look for power lines, making it suitable for urban or environmentally sensitive areas where visual impact is a concern.

Application

- Urban power grids:

It is applied in densely populated areas where overhead wiring is a problem to reduce the visibility of the wiring. They brought synergistically integrated layout solutions that occupy less space and have a more attractive design to blend into the urban environment. Such insulators have been used in some cities to replace old wires without increasing the cities’ sprawl of infrastructure.

- High-altitude installations:

In areas with challenging terrains, such as mountainous areas, it is selected for its lightweight and compact structure. These insulators reduce the logistical challenges of transporting and installing heavy equipment in remote areas. A notable case is the installation of cross-arm composite insulators in the Andes Mountains, where their ease of installation and durability in adverse weather conditions proved to be advantageous.

- Coastal and industrial areas:

They are used in places that are exposed to marine punishments, or areas that have high levels of pollution, around industries or chemical processing plants, among others, they are durability to salts, corrosive elements, and pollution. For instance, application in the coastal transmission line in Japan, and their inherent nature of being hydrophobic makes them cheaper to maintain and more reliable.

- Renewable energy projects:

Cross-arm composite transmission line insulators are also used in renewable energy projects like wind and solar farms where space is a constraint and hence the space saver compact line of products is essential. They help achieve the enhancement of the distribution of renewable energy generation with the least encroachment on the environment. A classic example is the use of SCADA systems in a large wind power plant in Northern Europe to enable the wind power to be fed into the country’s main power grid.

Exhibition

Certificate

Hot Tags: Crossarm Composite Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage