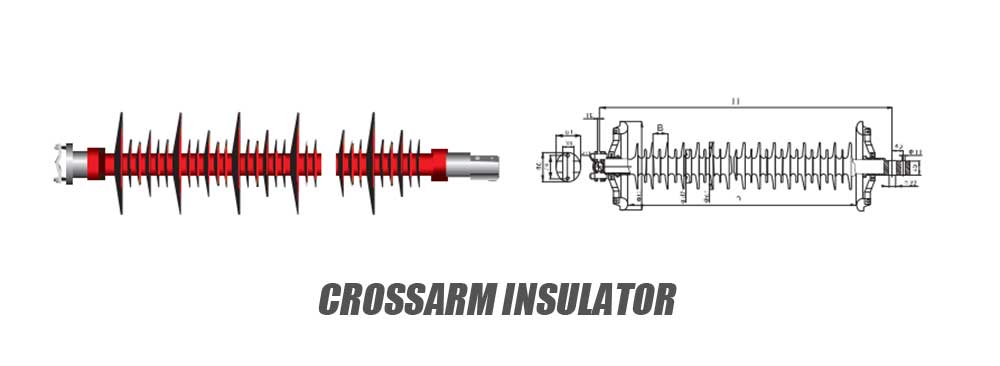

Specification

| Type of Insulator |

FS-220/0.25-MJ-2240 |

FS-220/0.5-MJ-2240 |

| Specified Voltage |

220 kV |

220 kV |

| Specified Mechanical Tensile Load |

0.25 kN |

0.5 kN |

| Section Length |

2240±30 mm |

2240±30 mm |

| Min. Arcing Distance |

2100 mm |

2100 mm |

| Big Shed Diameter |

190 mm |

250 mm |

| Diameter of GraDing Ring |

305 mm |

305 mm |

| Min. Nominal Creepage Distance |

6300 mm |

6300 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

≥1000 kV |

≥1000 kV |

| Power Frequency Withstand Voltage min. wet(RMS) |

≥395 kV |

≥395 kV |

| Reference Weight |

18 kg |

21 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

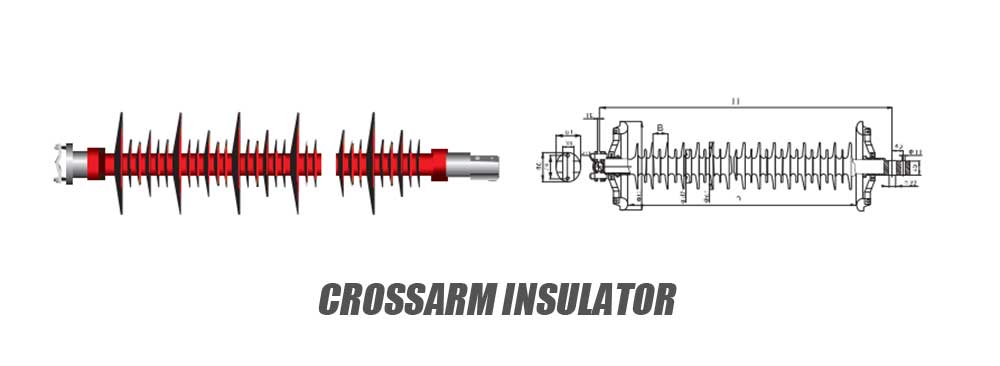

What is the Crossarm Insulator?

Crossarm Insulator is one of the most important accessories that is deployed in power transmission and distribution systems. Its main function is to protect the electrical conductors and to isolate them mechanically from the supporting structures, such as poles or towers to prevent the electrical current from passing through the support members and staying within the conductors. They are normally constructed from materials that possess high dielectric strength and mechanical endurance for example; porcelain, glass, or polymer composites. Crossarm insulators are installed on cross arms of utility poles or transmission towers, and they provide vital functions of preventing faults between phases or between phase and the neutral, or ground, as well as ensuring correct conductor separation and alignment. It is expected that various types of environmental stresses such as weathering, UV degradation, mechanical loading, etc., are to be withstood by polymer systems to provide long-term stability desirable for outdoor applications.

Unique Features

- Mechanical Strength:

Composite cross-arm insulators are intended to bear substantial mechanical loads since they have to hold loads of conductors and counteract forces such as wind and ice. This helps them be mechanically robust for efficiency outdoors which is a requirement that many of them face.

- Horizontal Installation:

In contrast to most of the other insulators, which are usually installed longitudinally, they are installed laterally on cross-arms of utility posts or pylons. This positioning is very critical so that the spacing of the conductors and other related alignments will be correct.

- Insulation and Support:

These insulators are multifunctional as they perform both electrical insulation as well as mechanical support. Besides shielding the current conductors from the flow of electricity to the supporting structures, they also safeguard the conductors physically.

- Custom Design:

They can also be specially tailored to fit various demands of the transmission and distribution systems. This flexibility makes it possible to offer the best solution depending on the application and the conditions in which it will be used.

Benefits

- Enhanced Safety:

Cross Arm Composite Insulator prevent electrical currents from passing through supporting structures, thereby reducing the risk of electrical faults and ensuring the safety of the system and personnel.

- Reliable Performance:

Made to be resistant to environmental factors such as weather elements, ultraviolet light, and pollution, it provides a dependable and long-term performance.

- Mechanical Strength:

Their robust construction supports the weight of conductors and resists mechanical stresses from wind, ice, and other environmental factors, maintaining the stability and integrity of the power lines.

- Improved System Efficiency:

Minimizing the distances, between conductors and ensuring proper alignment helps to decrease the possibilities of short circuits and power outages leading to the enhancement of the power transmission and distribution system.

- Durability:

Available in polymer composites, porcelain, or glass, it is highly durable and requires little maintenance thus cutting on more costs than other traditional materials.

- Flexibility:

With designs and materials available to choose from, it can also be adapted to the kind of electrical systems, and the surrounding environment; thus making it flexible and can be fitted to the situation demanded.

Application

- Distribution Networks:

About the overall distribution networks whether in urban or rural settings, it assists in the management of distance between conductors placed on utility poles to avert possible electrical faults and power blackouts.

- Railway Electrification:

It is applied in railway electrification to provide the overhead wiring that provides power to electric trains to guarantee uninterrupted electrical power.

- Wind Farms:

In wind farms, they are used to help conductors transport power produced by windmills with a view of guaranteeing a steady supply of renewable power to the grid.

- Solar Power Plants:

It is applied in applications such as solar power plants to support insulation and offer protection to conductors that interconnect the solar arrays with the power system to ensure efficient transference of solar power.

- Industrial Facilities:

It supports the conductors that furnish power to numerous machinery and equipment to affirm their secure and effective operation.

- Substations:

These are applied to substations for supporting and electrical insulating bus bars and other conductive equipment to ensure the reliability and safety of the substation.

- Remote and Harsh Environments:

Electric cross-arm insulators are well suited to be installed in areas that are remote or in adverse conditions like mountain and coastal areas since they are very resistant to environmental stress and very durable.

- Marine Applications:

In marine environments, it supports power transmission lines on docks and offshore platforms, ensuring reliable power supply in corrosive and challenging conditions.

About Wishpower

Certificate

Hot Tags: Crossarm Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage