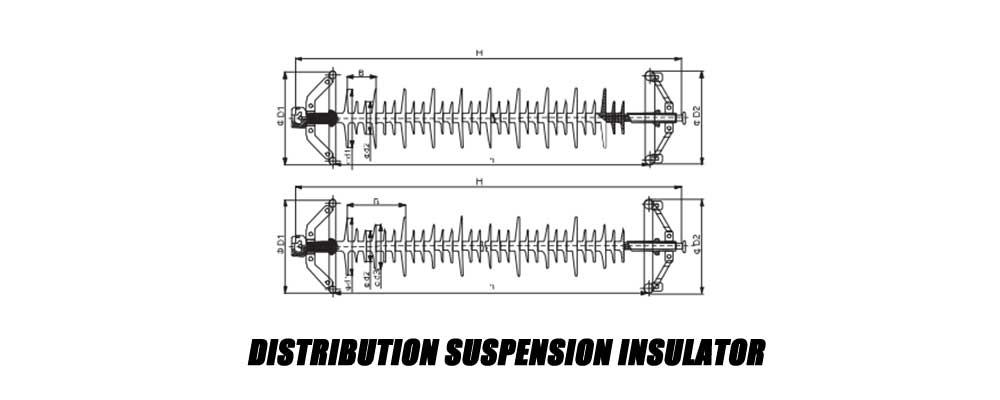

Product Specifications

| Core |

FRP rod |

| Sheds |

High-quality silicone rubber |

| Voltage Rating |

6 / 10 / 15 / 20 / 24 / 25 / 35 kV |

| Dielectric Strength |

35 kV/mm |

| Creepage Distance |

1000 mm |

| Tensile Strength |

80 kN |

| Compressive Strength |

60 kN |

| Torsional Strength |

50 Nm |

| UV Resistance: |

ASTM G154 |

| Pollution Class |

Moderate |

| Temperature Range |

-22°F to +122°F (-30°C to +50°C) |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

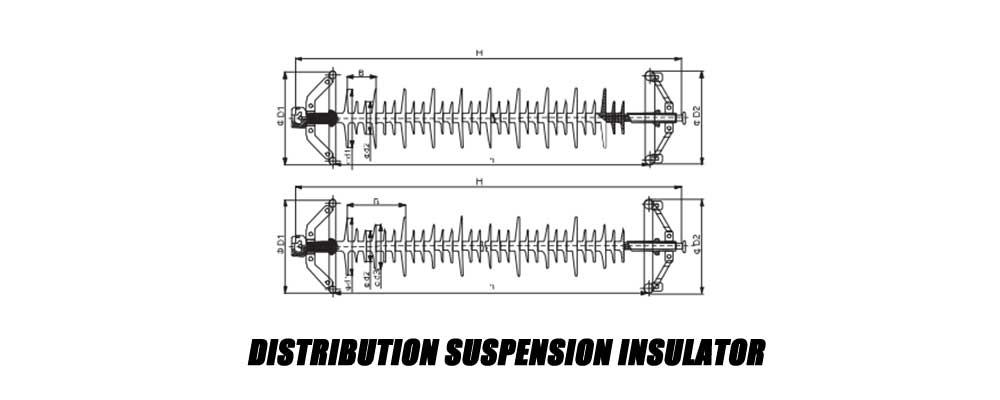

What is the Distribution Suspension Insulator?

Distribution suspension insulators are used in suspension distribution systems for supporting overhead lines and for maintaining electrical isolation in the power distribution system. These insulators are utilized in the medium voltage to high voltage systems of electrical power to make sure that the conductors are adequately spaced from the supporting structure to avoid the formation of faults. Wishpower’s insulators are generally produced from advanced materials such as composites, and they afford high mechanical strength, chemical and weather resistance, and electrical insulation. Those are meant to be resistant to external conditions including temperatures, humidity, pollution, and mechanical stress as well as guarantee durability as well as high performance. They are normally installed in a vertical direction where one end is provided with the conductor and the other end is connected to the supporting member such as a pole or tower. This design permits the conductor to be sagged below the insulator and gives flexibility to the line together with minimizing mechanical stress on the insulator.

Features

- Flexibility in Installation:

Compared with rigid insulators, suspension insulators enable the conductor to be suspended which offers flexibility given mechanical forces such as winds or earthquakes. This makes it possible now and then to change direction – the direction that was chosen initially – to minimize mechanical stress and damage to the conductor or the supporting structure.

- Superior Mechanical Strength:

It is designed to support the weight of the conductor and withstand environmental forces, offering higher mechanical strength compared to other types like pin insulators. This makes them suitable for longer spans and higher voltage lines.

- Effective for Higher Voltages:

These insulators are particularly effective in higher voltage applications. Their suspension design reduces the likelihood of flashover, which is a common concern in high-voltage systems. This makes them preferable in distribution networks where voltage levels are medium to high.

- Reduced Pollution Flashover Risk:

Distribution Suspension Insulators mostly hang vertically and are therefore not very susceptible to dust, salt marsh, and general pollution. This reduces the possibility of a flashover in a charred environment, hence increasing the reliability of the power system.

- Ease of Maintenance and Inspection:

Post or pin insulators have fittings in one end whereas suspension insulators have a fitting for the clamp on both ends so this makes suspension insulators easy to inspect and maintain. Malfunctioning units can be detected and replaced sometimes more easily, reducing time off in the power system.

Benefits

- Enhanced Safety:

The suspension design minimizes the chances of electrical faults by keeping conductors well-insulated from the supporting structures. This significantly enhances the overall safety of the electrical distribution system.

- Longer Lifespan:

In general, this composite suspension insulator is known to have a longer operational life because they are not easily affected by stresses in their environment and are not easily contaminated. This cuts down on the number of times a particular product will be replaced, thus cutting down on the amount of money needed to maintain the product.

- Greater Load Capacity:

These insulators can support heavier loads and longer spans without compromising stability, making them ideal for use in complex and demanding distribution networks.

- Improved Performance in Harsh Conditions:

For this reason, they can withstand pollution, moisture, and temperature fluctuations making it hard for them to trip hence discouraging power outages.

- Cost-Effective:

The durability and reliability mean that there are fewer replacement and repair costs incurred over time making them an efficient means of providing for the need for electrical distribution systems particularly high voltage systems.

Application

- Overhead Power Lines:

They are mostly employed in overhead power systems to suspend and also provide the required electrical insulation for conductors. They contain the leakage of electricity and guarantee that the high voltage current only flows through the conductor without intruding on the supporting structures and other neighboring objects.

- Railway Electrification Systems:

In railway electrification, these insulators are employed for suspension of the overhead wires which supply power to the electric trains. They are required to additionally bear mechanical force due to the weight of the wires and electrical force due to the voltage intensity.

- Substations:

They are also used in substations where they provide support and/or insulation for the busbars and other high-voltage equipment. These are useful in Metro Power Substation Limited for preserving appropriate electrical clearance and safe running of the substation equipment.

- Transmission Line River Crossings:

They are used where power lines cross rivers or other large water bodies; they serve to take up longer spans of the conductors. These insulators are meant to carry the additional mechanical load arising from the greater span of the structures where they are installed.

- Wind Farm Connections:

In wind farms, suspension type insulator is employed to interconnect turbines to the transmission system. They assist in making sure that the electrical energy produced by the turbines to the power grid is the correct energy with extra capacities not being supplied, or wrong frequencies supplied.

Certificate

Factory

Hot Tags: Distribution Suspension Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage