Specification

| Item |

Specification |

| Rated voltage |

6kV, 10kV |

| Rated capacity |

Maximum capacity of a single group 2000kvar |

| Number of groups |

Generally divided into 4 groups at most |

| Reactance rate |

Select according to actual conditions, such as 1%, 5%, 6%, 12%, etc. |

| Control mode |

Voltage reactive power control and power factor control |

| Protection function |

With overvoltage protection and undervoltage protection |

| Discharge time |

The complete set of equipment is equipped with a discharge coil, and its discharge performance meets the requirements that after the capacitor group is disconnected from the power supply, the residual voltage on the capacitor group will be reduced to 50V or less within 5s |

| Contactor life |

100,000 times |

| Structural form |

Cabinet type, box type |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net

What is the DWK Substation Reactive Power Automatic Compensation Device?

DWK substation reactive power automatic compensation device is designed for 35kV and 110kV substations, which performs well in power quality stability and energy efficiency optimization. The device monitors fluctuations in reactive power at the substation automatically and responds to real-time demand by automatically opening and closing capacitor banks. The DWK device manages reactive power carefully, improving the power factor not only to reduce network losses and as a result decrease energy losses, but also to increase the general quality of delivered power to end users. It is fast-acting and very sensitive to changes in reactive power, and thus the substation will operate at a maximum efficiency. It offers real-time control of intelligent reactive power that is stress-free to equipment and extends the life of the transformer and other critical components. Moreover, it reduces energy waste by decreasing the reactive current circulating in the substation offering energy savings for the substation and making power distribution more sustainable.

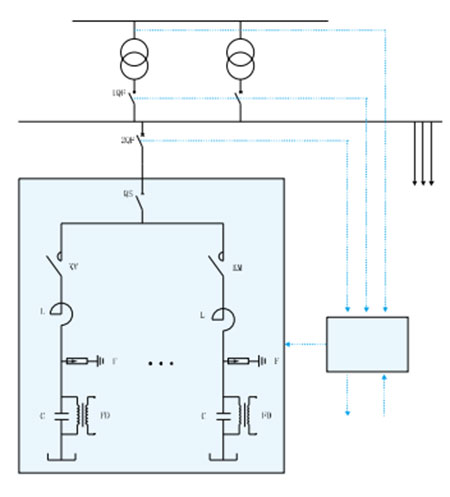

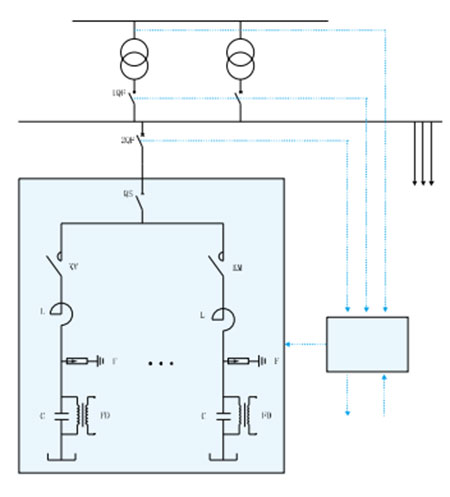

Composition Structure

Important components serve together to sense and control reactive power in high voltage substations, which make up the reactive power compensation equipment. The structure is an intelligent controller, vacuum contactors, dry-type iron core reactors, high voltage shunt capacitors, discharge coils, and surge arresters.

Intelligent Controller: The central processing unit of the intelligent controller is the intelligent controller; it continuously monitors reactive power levels and decides the best switching configuration for capacitor banks, to yield optimum power factor correction.

Vacuum Contactors: These are used to execute fast switching of chip capacitor groups for quick modulation of system reactive power demands and minimal system wear.

Dry-Type Iron-Core Reactor: It injects inductive reactance to attenuate switching transients and limit inrush currents when capacitances are connected, to ensure smooth operation and stability in high voltage environments.

High-Voltage Shunt Capacitors: The main role in reactive power compensation is played by the capacitors, first of all, they are used to change power factor and to maintain energy efficiency on a substation.

Discharge Coils: After switching, residual energy departs from these capacitors safely discharged to these coils, thereby eliminating voltage surges and ensuring the system’s safety.

Surge Arresters: An additional layer of safety for the device from overvoltages produced by lightning strikes or switching surges is performed by surge arresters.

Working Principle

The reactive power compensator is operated on the background of a complex system that continuously monitors and adjusts the reactive power level of high voltage substation in the setting of a particular need of required reactive power component from the particular grid point. This functionality is based on the core, which is the intelligent controller, the collection of real-time voltage and current data from the voltage transformers and current transformers installed at the substation. Once this data is received the intelligent controller uses an advanced algorithm to process this information and determine the current status of reactive power in the system. The controller then based on the calculation result, sends exact commands to vacuum contactors (capacitor banks) to be opened or closed in locations needing the capacitor bank. The switching can be on equal or unequal capacity according to the reactive power requirement at that time.

Features

- Real-time tracking and dynamic compensation:

Reactive power compensation is accomplished automatically, with the device monitoring changes in reactive power and changing the switching of capacitor banks accordingly for efficient reactive compensation.

- Coded switching and hierarchical compensation:

It supports non-equal capacity-coded switching of capacitors thus multiple-level compensation can be done using fewer circuits. The feature allows precise adjustment while enabling equal capacity multi-circuit switching when required.

- Flexible control mode:

The two control modes available in DWK devices are selected by the user based on the voltage and reactive power conditions at the installation point and the most appropriate control mode is chosen. This flexibility makes this device very easy to use in multiple scenarios.

- Vacuum contactor switching:

Vacuum contactors are for switching capacitor banks, compact, good arc extinction and long service life, low maintenance cost, and excellent safety, especially well applicable in applications with frequent operation. The contactor employs materials and technologies optimized for interrupting capacitor current.

- User-friendly intelligent controller:

It is an easy-to-operate stable and reliable device with a friendly human-machine interface. This design is better at improving user experience as well as operating efficiency.

- Comprehensive protection functions:

Powerful protection to prevent system damage in case of unexpected situations is available as reactive power devices.

- Multiple communication options:

It achieves seamless transmission and monitoring by supporting the means of communication; wireless communication modules and GPRS. Remote access to the system’s operating status is provided by this function for management and supervision.

Certificate

Factory

Hot Tags: DWK Substation Reactive Power Automatic Compensation Device, Voltage Regulator, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage