Specification

| Electrical parameters |

| Maximum operating voltage (kV) |

126 |

| Impact withstand voltage (kV) |

550 |

| Mechanical parameters |

| Maximum cable cross-sectional area (mm²) |

1600 |

| Maximum insulation outer diameter (mm) |

87 |

| Approximate total weight (kg) |

18.2 |

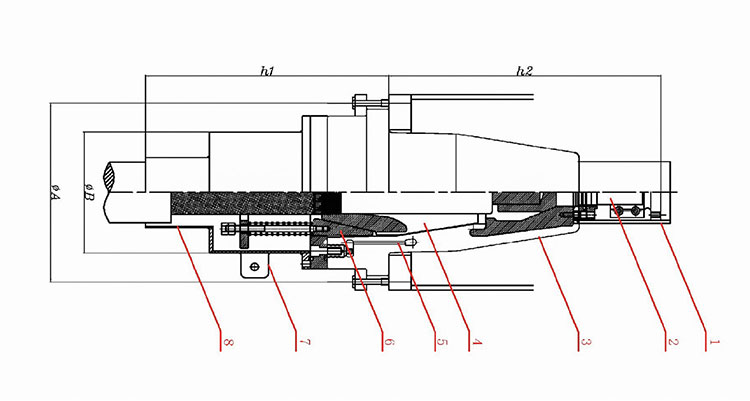

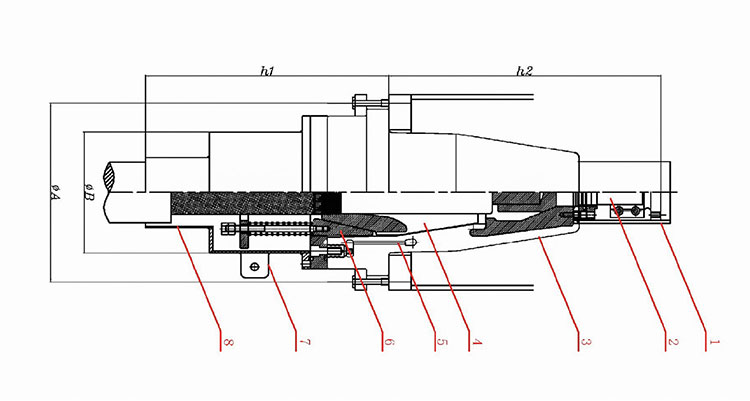

| Main dimensions |

| φA (mm) |

320 |

| φB (mm) |

219 |

| h1 |

435 |

| h2 |

470/ 757 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is GIS Dry-type Termination?

GIS Dry-type Termination is an electrical termination device intended for use in conjunction with Gas Insulated Switchgear (GIS) systems. Dry-type termination engineered for highly reliable and stable connection of high voltage power cables, no oil or gas medium used; solid insulation eliminates the possibility of leaks and maintenance needs. It is made from high-quality insulation materials, high dielectric strength, excellent dielectric loss, and high resistance to dielectric stress. The Termination is designed in a compact format, allowing for the optimized use of space within switchgear systems suitable for installations in confined or indoor areas of low clear space. Furthermore, dry construction enables environmental compatibility by safe operation without insulating fluids, providing both performance stability as well as minimal environmental impact in modern high-voltage networks.

Features

- Fully Pre-molded, Oil-free, and Spring-compressed Dry Structure:

This GIS termination has a fully pre-mold design as a dry type with constant force springs for compression of the connection. This oil-free structure removes the chance of oil leakage leading to failure, and this also promotes reliability and environmental protection.

- Flexible Installation Angles:

Versatile install options allow for connection upright, horizontally, inverted, or any other angled position. This flexibility can support complex layouts and meet unique installation requirements.

- Adjustable Conductor Lead-out Structure:

Intended for easy connection with high voltage equipment such as switch gear and transformer, the termination has a lead-out structure that can be adjusted, affording placement of the conductor to best accommodate connectivity and design.

- Compact and Space-efficient Design:

The structure of this termination is compact and streamlined, minimizing the required space to be used in a confined environment with no increase in system footprint at the expense of performance.

- Compliant with IEC 859-1999 Standards:

The GIS cable termination is designed following IEC 859-1999 standards to guarantee maximum quality, safety, and compatibility of the high-voltage systems in the international field of operation.

- Convenient On-site Installation:

Its design makes termination easy to install on site so it can be handled easily and has quick change over time. This is especially useful if a quick and flexible installation is required for complex or time-dependent situations.

Main Components

- Standard Interface:

The standard interface of the termination is made from T2 copper and will provide a secure and reliable interface point thus enabling the termination to interconnect seamlessly with different high-voltage equipment while maintaining excellent conductivity.

- Conductor Rod:

The conductor rod itself is made of T2 copper, which means it has high conductivity which is necessary to have stable performance in high-voltage applications.

- Epoxy Sleeve:

The sleeve is made of epoxy resin which is constructed to provide robust insulation and mechanical support to internal components, protecting them from environmental factors and electrical stress while guaranteeing structural stability.

- Stress Cone:

The stress cone control (stress cone control) is made of liquid silicone rubber and supplies and evenly distributes the electrical stress in the termination. It improves insulation reliability while reducing the chances of electrical discharges.

- Grounding Electrode:

The grounding electrode is made up of copper having a secure grounding point for dissipating extra electrical charge and safe working of the system.

- Cone Support:

An aluminum cone support provides mechanical stability to the stress cone to keep it in position and allow it to perform under different operating conditions.

- Grounding Copper Bar:

A copper fabrication of this grounding bar is used and is reliable grounding connection ensures safety as there is no hazard due to electrical incident.

- Metal Tail Tube:

The GIS Termination Kit is made from copper, a conductive extension at the end of the metal tail tube provides additional protection and connects to connected equipment smoothly.

Certificate

Factory

Hot Tags: GIS Dry-type Termination, Cable Accessories, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage