Specification

| Type of Insulator |

FJYHC-1.5/4.5-1000 |

| Specified Voltage |

1.5 kV |

| Specified Mechanical Tensile Failing Load |

70 kN |

| Specified Mecharical Berding Load |

4.5 kN |

| Section Length |

1000 mm |

| Min Insulation Distance |

130*2 mm |

| Min. Nominal Creepage Distance |

250 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

125 kV |

| Power Frequency Withstand Voltage Test- Wet |

30 kV |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is the Insulation Brace Insulator?

Insulation Brace Insulators Using advanced composite materials, they are state-of-the-art insulators utilized for mechanical support of the conductors together with electrical insulation in electric transmission as well as distribution networks. These body insulators are tailored to withstand mechanical loads such as wind; vibration; and mechanical loads and at the same time should be able to insulate optimally. The composite material, which may be a fiberglass epoxy material or other polymers provides enhanced strength and elongates the body of the insulators to a greater extent of strength-to-weight ratios than porcelain or glass insulators. These insulators are designed to exhibit good performance characteristics in hostile environments such as polluted, salt fog, or vane environments. This is because the composite material has a high tracking and erosion-resistant factor; thus minimizing the chances of flashovers and the composite material has a long service life. Also, the composites are known to have a low affinity for water and this characteristic assists in reducing the probability of the formation of a layer of contamination over the surface of the composite, and helps in improving the insulation of the material.

Features

- Mechanical Strength:

Epoxy support insulators outperform porcelain insulators in terms of tensile strength and flexibility; hence, they are less susceptible to cracks under mechanical stress such as wind and vibration.

- Pollution Performance:

These insulators are hydrophobic so they cannot allow contaminants on their surfaces as compared to glass/porcelain where contamination is evident and frequent cleaning is required in polluted regions.

- Lightweight Design:

The insulators constructed from composite materials are much lighter than their counterparts that were constructed from traditional materials, thus they are easier to install, the weight of these insulators does not exert a lot of pressure on the structures that support them.

- High Resistance to Environmental Factors:

It also provides high resistance to UV rays, chemicals, and temperature fluctuations to provide optimum results in various surroundings.

- Hydrophobic Properties:

Its surface naturally repels water, reducing the risk of surface currents and flashovers, thereby improving the overall reliability of the electrical system.

- Enhanced Safety:

Another advantage is that it does not break easily and this is advantageous in uplifting and while in use particularly in high voltage systems.

Benefits

- Improve system reliability:

By effectively supporting conductors and preventing mechanical failures, braced post-insulators help ensure continuous and reliable power transmission, minimizing blackouts and interruptions.

- Optimize power flow:

It maintains a steady flow of power by reducing energy losses from leakage or faults, thereby improving the overall efficiency of transmission lines.

- Extend the life of infrastructure:

Reducing wear and tear on conductors and other components due to movement or environmental exposure helps extend the life of transmission infrastructure.

- Reduce operating costs:

Reducing maintenance needs and avoiding frequent repairs reduces the operating costs of maintaining transmission lines, making it a cost-effective option in the long term.

- Enhanced performance in challenging environments:

They work best in polluted areas or in regions that are close to the seashore where most other kinds of insulators may break down or provide very low power transmission reliability.

- Improve load management:

Handling a greater amount of load and distance without requiring extra reinforcement of the structure, allows improved loading conditions and optimizes the utility of transmission lines.

Application

- High-voltage transmission lines:

One of its uses is in high voltage transmission line work where it offers mechanical support and insulation to conductors particularly when it has a long span. They assist in maintaining line stability and prevent cases of flashovers, this makes the electric power supply long-distance reliable.

- Substation equipment:

In substations, these insulators are employed for supporting and as insulating elements for the busbars and circuit breakers among others. They are capable of handling high electrical and mechanical loads and are best suited to ensuring the safety and stability of substation services.

- Urban power distribution:

It is used to keep conductors off structures or other conductors and as such offer support to overhead lines. Due to their small size and low total weight, they are ideal for areas with high congestion and or where restriction on space and load is paramount.

- Coastal and polluted areas:

They are preferable, especially in the areas that experience high pollution and the coastal areas where pollution attacks affect the traditional non-pollution insulators. It possesses high levels of resistance to include the effects of vandals, salty atmosphere, fumes, and other chemicals.

- Wind and solar farms:

This support insulator is also used in renewable facilities occasionally including wind farms, solar farms, and the like. They offer the appropriate barrier and structural framework to hold the electricity cables that supply the turbines and solar panels linked to renewable sources of power to the grid to strive to guarantee constant and safe electricity delivery.

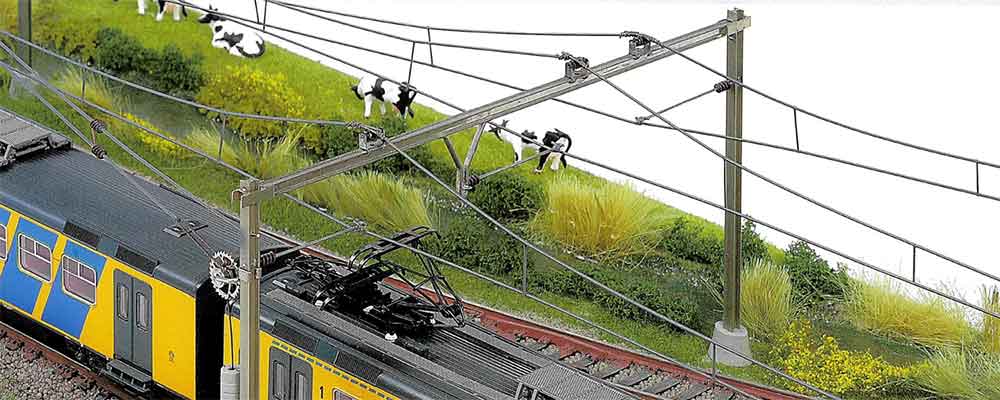

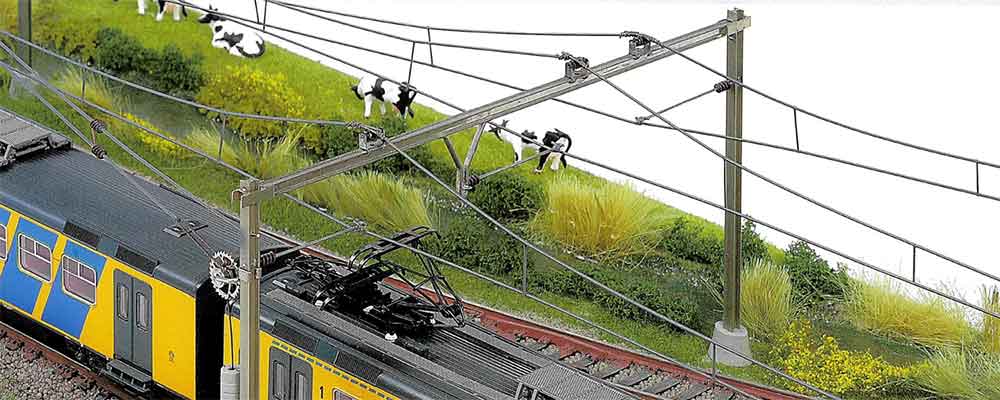

- Railway Electrification System:

In railway electrification, its role is to hold up the overhead contact wires that supply power to trains. It is significant for the electrified railway systems to have good mechanical performance and electrical insulating properties which is evident in this product.

Exhibition

Certificate

Factory

Hot Tags: Insulation Brace Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage