Specification

| Type of Insulator |

FZSW-220(252)/4 |

| Specified Voltage |

220 kV |

| Specified Bencing Withstand Load |

4 kN |

| Section Length |

2300±5 mm |

| Min. Arcing Distance |

2312 mm |

| Big Shed Diameter |

210 mm |

| Min. Nominal Creepage Distance |

6300 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

≥1050 kV |

| Power Frequency Withstand Voltage Min.Wet(RMS) |

≥460 kV |

| Reference Weight |

48 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

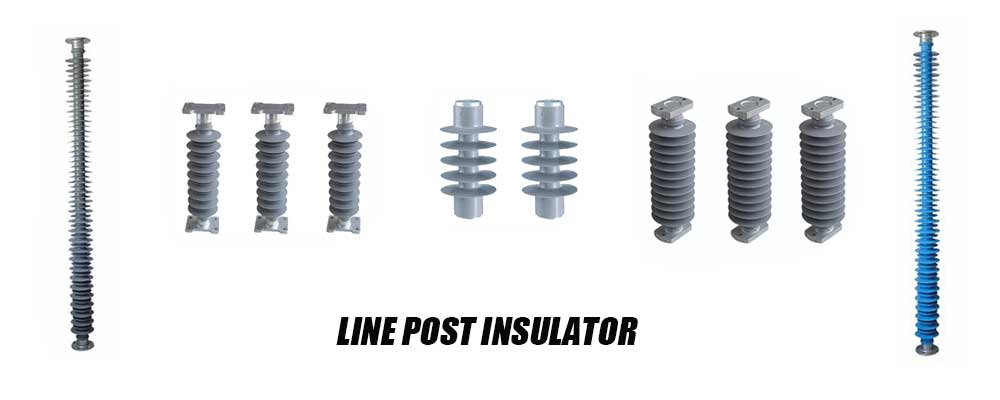

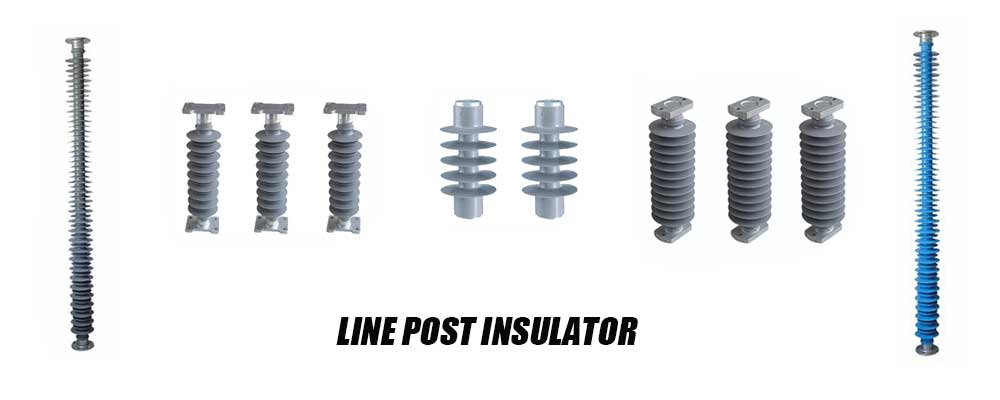

Line post insulators are widely used in power distribution and transmission systems. They can withstand mechanical and environmental stresses, support and insulate conductors, and play an important role in the reliable transportation of electricity. Wishpower has been deeply involved in this industry for more than 20 years. Through continuous research development and innovation, it has become a reliable supplier for customers in different countries and industries.

What are Line Post Insulators?

Line post insulators are an important component in high-voltage transmission lines, used to support and fix conductors while providing the necessary electrical insulation. These insulators are usually installed on the cross arms of utility poles or transmission towers. They can withstand huge mechanical loads, including vertical and horizontal forces, ensuring that the conductors remain firm in adverse weather conditions such as strong winds, ice, or heavy rain. Their high resistance prevents current from leaking to the supporting structure, thereby maintaining the integrity and safety of the transmission line. They are mainly produced by porcelain or ceramic enamel, glass, or composite materials. Each of these materials has its properties and therefore if there is a certain usage strategy, then probably that particular material is the right one to be used. Their surface is generally treated to resist contamination by dust, salt, and industrial pollutants, which can degrade electrical performance. In areas with higher pollution levels, these insulators are designed with special shapes to minimize the accumulation of pollutants, promote self-cleaning during rain or flushing, and maintain high electrical performance even in polluted environments. Wishpower will recommend or customize the most suitable products and solutions for you according to your usage scenario.

Post Insulators VS Fence Insulators

Similarities:

Both provide electrical insulation features, which means that current cannot flow through the support structure. They can both be constructed of hard insulating materials such as ceramics, glass, and composites.

Differences:

Post-insulators are mainly applied in transmission and distribution networks of electricity to hold conductors and provide safety. They have to bear fairly large mechanical loads. This involves both the vertical and horizontal forces for adverse conditions in the weather situation. It has features aimed at protecting the structure from severe environmental conditions including torque, heat, cold, wind storms, hail, ice, and snow. They are mostly useful in applications with high-voltage transmission capabilities and can endure voltages of several hundred kV.

Fence Insulators are mainly used in electric fence systems – essentially, in agriculture and industries mostly using electric fences. It is characterized by lower mechanical strength needs in comparison with other materials. They only need to support the electric fence wire and maintain electrical isolation between it and the supporting posts. They are also used in outdoor environments but do not need to withstand the extreme conditions of high-voltage power systems. They are suitable for low-voltage applications, usually for voltages within a few thousand volts.

Benefits

Electric post insulators are mainly used to sustain the vertical and horizontal mechanical forces in the transmission of high-voltage electrical energy. So that the conductor can be installed firmly on windy areas, or any cold atmosphere such as through ice and snow, and cannot be blown or tilted by force majeure.

- Excellent electrical insulation performance:

It possesses high electrical impedance and can quite well avoid the leakage of current to the supporting structure. Maintain safety in the handling of electrical power and the safety of electrical devices and appliances in operations that involve the use of high voltage.

- Material diversity:

They can be of ceramic, glass, and composites which have their benefits in view. Ceramic insulators have a longer life, glass insulators can easily be noticed and seen and composite insulators are comparatively, lighter and possess a very high degree of damage tolerance.

- Strong environmental tolerance:

These insulators are specifically made to fit in places that experience severe weather conditions. These are; high temperature, low temperature, humidity, snowfall, and salt spray. The surface is generally made to have a repellent characteristic that prevents the build-up of pollutants on it and can be used for different harsh working conditions.

- Self-cleaning ability:

They are designed with self-cleaning ability in mind. The special shape can automatically remove pollutants on the surface under rain erosion and maintain excellent electrical performance, which is particularly suitable for areas with heavy pollution.

- Low maintenance requirements:

Due to the durability of the material and surface treatment technology. They generally require less maintenance, have low long-term use costs, and reduce power outages and maintenance workload.

- Installation flexibility:

They can be installed in different configurations. Including vertical and horizontal installation, adapting to various transmission line design requirements, and providing great flexibility.

- High voltage tolerance:

They are capable of withstanding several hundred kilovolts making their operations reliable and safe for high-voltage transmission a factor that low-voltage insulators cannot offer.

Application

Composite post insulator is widely used in high-voltage transmission lines and power distribution systems. They are mainly used to support and fix conductors while providing necessary electrical insulation. They are mostly mounted in substations, distribution equipment, power poles, and towers, capable of withstanding mechanical loads as well as mechanical and electrical stresses under adverse weather conditions. On account of aspects such as superior mechanical strength and electrical performance, they pose a significant role in guaranteeing the reliability of power transmission.

About Us

Exhibition

Hot Tags: Line Post Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage