Specification

| Bracket Type |

No Bracket |

| Type |

Cutout |

| BIL |

110 kV |

| Creep and Leakage Distance |

319mm |

| Current Rating |

100 A |

| Fuselink Current Range |

1A to 100A |

| Reference Voltage Limit – Minimum |

Thru 14.4kV |

| Temperature Rise – Max. at 300A |

38° C |

| Voltage – Maximum |

15 kV |

| Voltage – Radio Interference |

Ambient @ 9.41kV |

| Voltage Rating |

15 kV |

Wishpower has more than 20 years of production and R&D experience since its establishment. We are deeply engaged in Electrical & Grid, Rail Transit, Green Energy & Energy Storage products, only to provide professional products and solutions to customers worldwide. Please get support directly through this website or info@wishpower.net

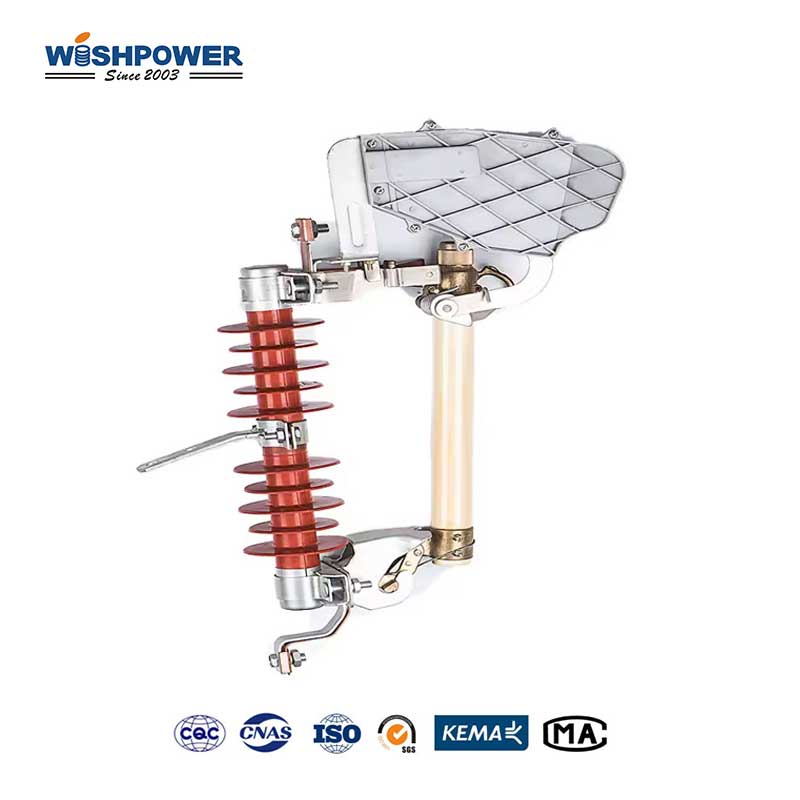

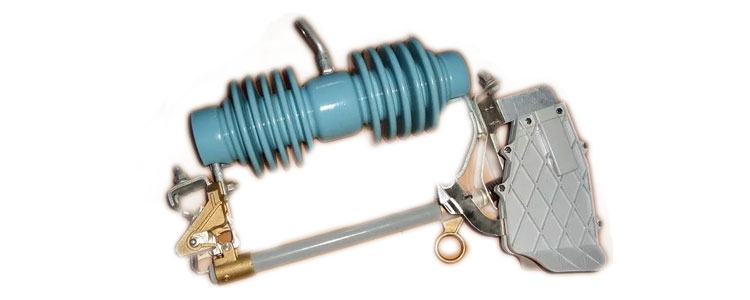

What is Loadbreak Polymer Cutout?

Loadbreak Polymer Cutout is an advanced protection device in power distribution systems that utilizes polymer materials for enhanced performance. It is designed to safely interrupt and reconnect circuits under load, making it essential for operational flexibility and maintenance in modern power networks. The use of polymer materials provides several advantages, including lightweight construction, increased resistance to environmental degradation, and superior insulating properties. This makes it particularly well-suited for outdoor applications in harsh environments. The key feature of this cutout is its loadbreak capability, which is achieved through specialized arc-quenching mechanisms that safely control and extinguish electrical arcs during load switching. This allows utility personnel to perform maintenance and operational tasks without de-energizing the entire system. It is commonly used in primary feeder lines, enabling the sectionalizing of distribution networks, switching capacitor banks, and protecting and switching transformers. Their ability to handle load currents and frequent switching operations makes them ideal for urban and industrial settings where reliability and safety are paramount.

Features

- Load Interrupting Capability:

Specifically designed to safely interrupt and reconnect circuits under load, crucial for maintenance and operational flexibility.

- Polymer Construction:

Loadbreak fuse cutout is made with advanced polymer materials, offering lightweight construction, superior weather resistance, and enhanced durability compared to traditional materials.

- Arc-Quenching Mechanism:

Equipped with specialized arc-quenching devices that effectively control and extinguish electrical arcs during load switching, ensuring safe and reliable operation.

- Versatile Applications:

Suitable for use in primary feeder lines, enabling sectionalizing of distribution networks, switching of capacitor banks, and protection and switching of transformers in urban and industrial settings.

Benefits

- Enhanced Operational Safety:

Loadbreak polymer fuse cutout facilitates isolation and restrikes of circuits under load which relaxes the chances of electrical disasters during maintenance and operations.

- Durability and Longevity:

Made of sturdy polymers to deter UV radiation, corrosion, and other weather conditions the life span of the device is to be as extended as possible.

- Maintenance Flexibility:

enables utilities to do needed work on the systems without blackouts, enhancing the operation of distribution grids.

- Lightweight Design:

The polymer construction also entails a lighter device and this makes the installation and handling easier hence cutting down the expenses of labor and equipment.

Application

- Primary Feeder Lines:

Used in primary feeder lines to enable safe switching and sectionalizing of the power distribution network, allowing for targeted maintenance and minimizing outage areas.

- Urban Power Distribution:

Ideal for urban environments where frequent load switching is required to manage and balance the power distribution system effectively.

- Renewable Energy Systems:

Deployed in renewable energy installations, such as solar or wind farms, to safely disconnect and reconnect circuits under load for maintenance or operational adjustments.

- Industrial Facilities:

Loadbreak cutout is used in industrial settings where reliable load switching is critical for maintaining continuous operations and ensuring the safety of high-value equipment.

Certificate

About Wishpower

Hot Tags: Loadbreak Polymer Cutout, Fuse Cutout, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage