Specification

| Rated Capacity(KVA) |

75 |

112.5 |

150 |

225 |

300 |

500 |

750 |

1000 |

1500 |

2000 |

2500 |

| HV/v |

4160 7200 12000 12470 13200 13800 19920 24940 34500 |

| LV/v |

110 220 230 400 480 |

| Connection Symbol |

Delta-Wye Dyn1 Ynyn0 |

| Standard |

IEEE ANSI DOE |

| Short-circuit Impedance(%) |

4%-7% |

| Efficiency (%) |

99.02 |

99.12 |

99.15 |

99.24 |

99.27 |

99.36 |

99.4 |

99.43 |

99.49 |

99.51 |

99.53 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net

What is the Oil Distribution Transformer?

The main application of the Oil Distribution Transformer is to reduce the power level from the transmission grid that is of high voltage so that they are suitable for distribution into the local residential, commercial, or industrial areas at lower voltage levels. It works on mineral oil which is used as a coolant and insulating medium. It absorbs the heat that is generated in the transformer’s operation and dissipates it, at the same providing insulation to windings and core thus avoiding electrical faults, and making it safer together. Electricity must be sent safely and efficiently over short distances in the distribution system. Oil distribution transformers are generally installed outdoors or in substations in outer rugged oil tanks to protect from environmental factors. The rig is designed with a strict emphasis on efficiency and durability and can operate continuously under changing load conditions without the risk of overheating. These transformers also include protection means, like temperature monitoring and pressure relief mechanisms, to prevent them from working until they eventually cause massive damage or bring movable things down to deadly levels.

Can it only be used for alternating current(AC)?

The design and working functionality of the Oil immersed transformer is mainly dependent on the electromagnetic induction process of alternating current, thus oil-immersed transformers are normally used in alternating current (AC) systems. The primary winding generates an alternating current in which an alternating magnetic field will be produced, which will induce the flowing current of the iron core of the transformer and will create voltage in the secondary winding. AC systems do this process specially optimized for this process; therefore they are mostly used to convert low-voltage AC, high to deliver to the end user. Because of the different characteristics of DC systems with AC systems, it has not been possible to introduce effective voltage conversion through the electromagnetic induction principle on traditional transformers. Also, DC does not have an alternating magnetic field, so standard transformers can’t work.

Advantages

- Efficient Cooling:

The liquid-filled transformer uses its oil to dissipate heat generated during operation, making the transformer cool even with a heavy load, thus keeping the transformer’s efficiency high, and preventing overheating at the same time.

- High Insulation Strength:

This makes oil an excellent electrical insulator, which in turn minimizes safe risks from high voltage components short-circuited or electrical discharge.

- Durability and Longevity:

Oil transformers are a long-lasting device as the nature of the oil keeps the transformers well protected from physical degradation as well as electrical faults over a long period.

- Cost-Effective:

For high capacity systems, tend to be generally more cost-effective on initial cost as well as maintenance costs, compared to some other alternatives.

- High Power Handling:

They can also sustain high power, and can comfortably be utilized in industrial, commercial, and utility environments, and they are delivered at high voltage and high capacity.

Market Trends

Many key factors impact its market trends including growing demand for reliable electricity supply, expanding renewable energy, and diminishing investments in renewable energy. Countries are emphasizing transforming the way power is distributed and the transformer of choice today both for efficiency and disaster proofing and meeting the high voltage tolerance has been gaining momentum. In addition, the oil-based transformer has benefited from technological developments in the design and materials from which they are constructed resulting in greater efficiency and environmental friendliness. In line with global sustainable development goals, manufacturers are now pushed to create transformers that minimize environmental footprint while maximizing performance.

Certificate

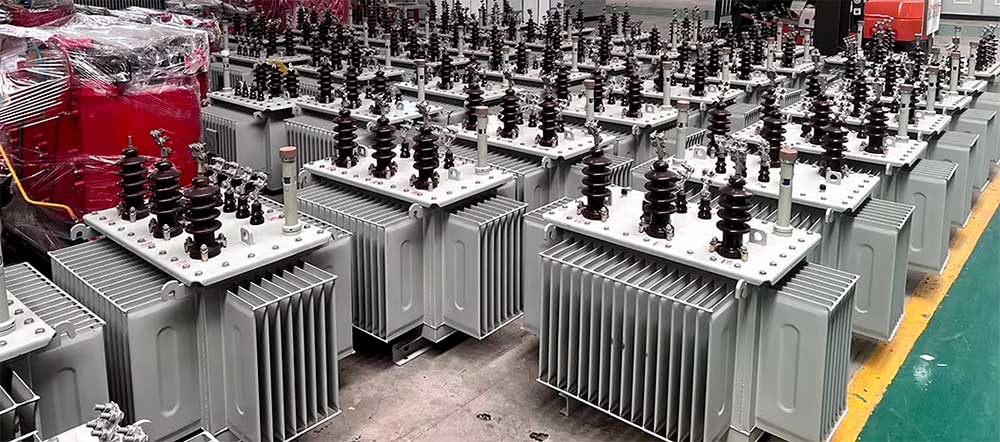

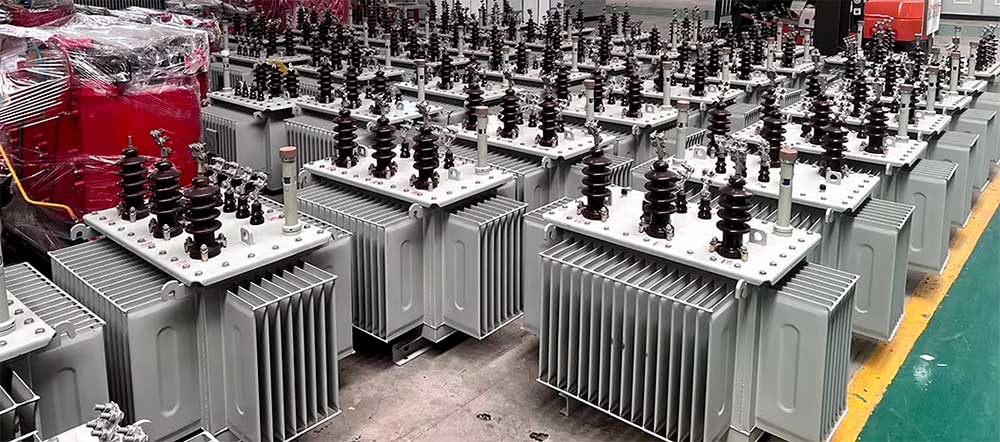

Factory

Hot Tags: Oil Distribution Transformer, Transformer, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage