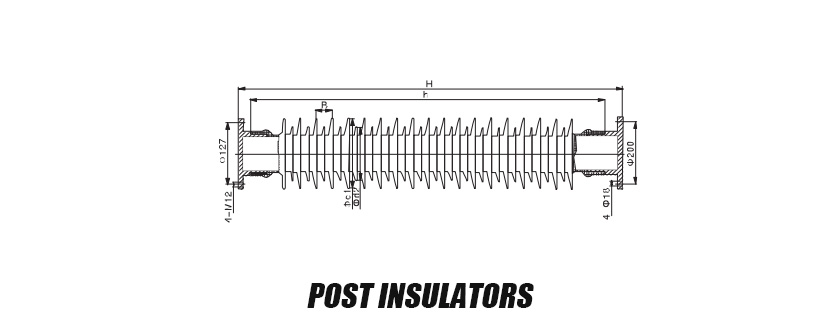

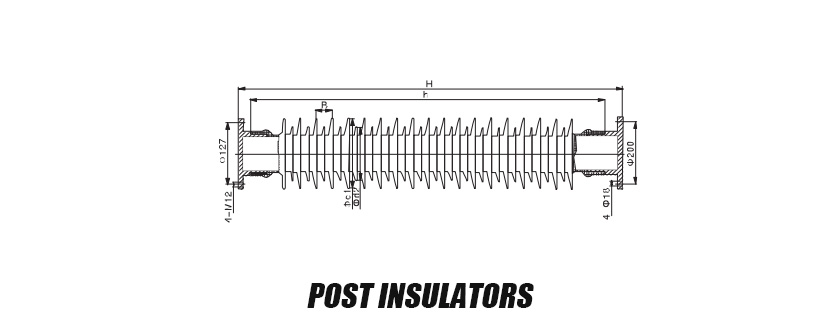

Specification

| Product Type |

FZSW-220(252)/4 |

| Specified Voltage |

220 kV |

| Specified Bencing Withstand Load |

4 kN |

| Section Length |

2300±5 mm |

| Min. Arcing Distance |

2132 mm |

| Big Shed Diameter |

210 mm |

| Min. Nominal Creepage Distance |

6300 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

≥1050 kV |

| Power Frequency Withstand Voltage Min.Wet(RMS) |

≥460 kV |

| Reference Weight |

48 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What are Post Insulators?

Post insulators are those types of insulators that are installed in the electrical systems primarily for support and at the same time separate the electrical conductors and also for insulation. They are used in substations, switchgear, and overhead wires and are preferred over other cable types due to the following; They can bear mechanical and electrical stresses, such as the load of the conductor or other physical forces in the environment example, wind and temperature-sensitive loads. In a general aspect, Wishpower mainly produces insulators from material composites. They have a central core and an outer skirt to achieve the greatest leakage distance as well as enhanced performance during extremes of temperature about the center lines. They are primarily utilized for insulating busbars, circuit breakers, and other parts that are used in high-voltage systems. These are indispensable for the protection of the power system from short circuit currents and the provision of adequate electrical insulation.

Unique Features

- Structural rigidity:

The composite line post insulator is a rigid, self-supporting structure. It is designed to be installed either vertically or horizontally for consistent and firm support of conductors and equipment.

- Mechanical strength:

It has high mechanical strength to support heavy equipment such as bus bars and switch gear parts. For instance, it is commonly applied in substations because of the many stressful conditions prevailing there.

- Creepage distance:

It has an extended skirt to maximize the creepage distance it was designed with. It does this to enhance performance in places where environmental conditions are very bad such as places that are polluted or where there is a lot of rain.

- Application environment:

It is particularly applied in substations and indoor switchgear where support and compactness of the structure are vital.

- Installation direction:

It is installed vertically or horizontally, usually on a solid structure such as a substation frame.

Benefits

- Space efficiency:

Since electric post-insulators allow for the design of compact substations, many are useful in high-voltage systems.

- Easy maintenance:

They are simpler in terms of several components and have a robust design, hence they have a lower maintenance rate and therefore are subjected to less time off.

- Versatile:

Designed for both indoor and outdoor applications, it is also rather versatile when it comes to the electrical application it is to be used in.

- Higher safety:

Electric power systems are made safer by their robust anatomy and effectiveness in insulation. This minimizes the risk of electrical failures and the risks of exploded wires in conflict regions especially the Black colors wires which may lead to explosions.

- High reliability:

By their design, they can endure unfavorable weather conditions. This gives a stable performance for a long time hence minimizing system breakdowns.

- Cost-effective:

In terms of operator costs, they are comparatively more efficient than all the other insulators as they involve little maintenance and replacement during their lifetime.

- Customizability:

They can be adjusted to particular voltage ratings and mechanical loading, thus suitable for different uses.

Application

- Power Generation:

Utilized in power stations to support and specially protect high voltage equipment such as bus bars and transformers.

- Transmission and Distribution:

The critical support structures of conductors and switchgear can be used in high-voltage transfer and distribution.

- Renewable Energy:

Applied on utility poles, buildings, and solar and wind farms for protection and support of electrical equipment that conveys energy.

- Railways:

Employed in electrified railways to bear and provide electrical insulation of overhead wires and other structures.

- Industrial Manufacturing:

Common in industries with large electric systems like steel producers, chemical industries, and in the manufacture of electricity such as the substation industries.

- Petrochemical Industry:

Station post insulators are employed where conditions are severe. Electrical insulation is rather critical to avoid risk, for instance, in the refineries and the gas processing plants.

Exhibition

Certificate

Hot Tags: Post Insulators, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage