Specification

| Electrical parameters |

| Maximum operating voltage (kV) |

40.5 |

| Impact withstand voltage (kV) |

200 |

| Power frequency withstand voltage (kV) |

117 |

| Partial discharge 45kV (pC) |

<10 |

| Mechanical parameters |

| Maximum cable cross-section (mm²) |

630 |

| Maximum insulation outer diameter (mm) |

55.3 |

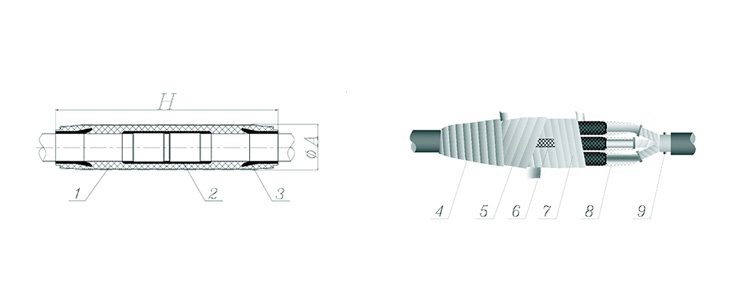

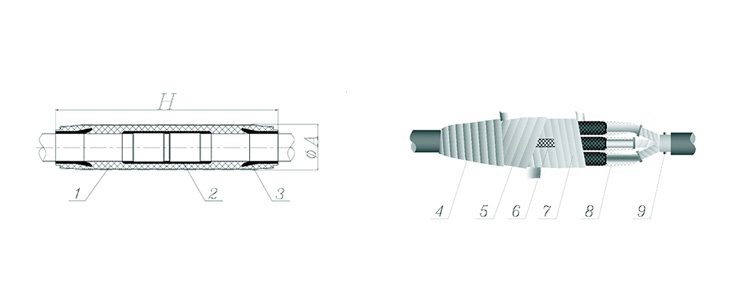

| Main dimensions |

Mix.-Max. |

| H (mm) |

455-550 |

| φA1 (mm) |

74-100 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is the Pre-molded/ Cold Shrink Joint?

Pre-molded/ Cold Shrink joint is a complete enclosure for the cable electrical insulation hence manufactured without heat or open flames during the installation. However, this joint is particularly prized for its relative ease of installation—often with an elastomeric (i.e., pre-expandable) material, commonly silicone rubber—an installed core that can be removed. Once over the cable joint area, the core is removed to enable the elastomer to contract as a tight waterproof seal over the cables. This cold shrink technology provides a consistently high level of insulation while reducing the risk of human error or environmental impacts from Heat shrink methods. They are well suited for high-voltage applications and environments where clean, safe installations are a priority. Additionally, they’re outstandingly durable against moisture, UV exposure, and environmental stresses and are great for outdoor and indoor use. They also feature a long operational life, and stable performance across various applications and conditions that withstand temperature variations, ozone, and chemical exposure.

Features

- Internal Stress Cone Structure

Pre-molded/ Cold Shrink Joint’s internal stress cone design also helps distribute electrical stress more evenly in the joint. The operational experience of proven safety and reliability is what that (feature) provides.

- Silicone Rubber Composition

The joint has been manufactured from liquid silicone rubber so that it provides sufficient compression on the cable insulation interface to produce a tight, stable seal that maintains high insulation integrity over time.

- Patented Installation Method

A patented method is used for the installation of the joint, for a simple procedure, while maintaining the quality of installation at the highest level. It aids in the assembly of this with consistent accuracy and little possibility for errors.

- Outer Protective Material is customizable.

The Joint is equipped with customizable outer protection materials to maintain operational needs. Among many other applications, these materials can be tailored to environmental conditions or user requirements.

- Specially Designed Connector Tube

A specially designed connector tube is provided to the joint to provide an equipotential contact with the inner shielding layer. Electrical stability is also improved and potential fluctuations are minimized.

- Approved for Direct Burial and Cable Trenches

Suitable for both direct burial and installation in cable trenches, the joint provides a versatile installation method in different environments.

Main Components

- Center Joint

This core part is made of liquid silicone rubber, offering secure linking and continuous insulation continuity between cable ends to ensure the electrical and mechanical integrity of the joint.

- Shielding Tube

This tube is composed of semiconductive adhesive from which a shielding layer composed of a semiconductive adhesive is formed to contain electrical fields inside of the joint and maintain stable conductivity.

- Stress Cone

The stress cone, formed from the same semiconductive adhesive, evenly distributes electrical stress around the cable interface to improve insulation reliability.

- Waterproof Tape

This tape is made from ethylene propylene rubber (EPR) to make a moisture barrier around the joint that keeps water out and stops from water getting in to jeopardize insulation performance.

- Armor Tape

The armor tape is constructed of fiberglass but provides an additional layer of mechanical protection reinforcing the joint for toughness and potential external impacts.

- Grounding Copper Tape

This tape is made from T2 copper which makes it suitable for good grounding of joints to dissipate stray electrical currents.

- Waterproof Belt

This joint is made from PVC term which when seems to mean another layer adds waterproofing to protect us from moisture. That means this joint is in harsh environments.

- Grounding Copper Mesh

This mesh is composed of T2 copper which serves as an additional grounding layer, helping to make the grounding contact generally evenly distributed around the joint and thereby contributing some electrical stability.

- Constant Force Spring

This spring is made of nonmagnetic stainless steel, keeps constant pressure over time, secures the Pre–molded/ Cold Shrink Joint, and performs with stable pressure in fluctuating environmental conditions.

Certificate

Factory

Hot Tags: Pre-molded/ Cold Shrink Joint, Cable Accessories, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage