Specification

| Electrical parameters |

| Maximum operating voltage (kV) |

40.5 |

| Impact withstand voltage (kV) |

200 |

| Power frequency withstands voltage (kV) |

117 |

| Partial discharge 45kV (pC) |

<10 |

| Creepage distance |

Ⅳ |

| Mechanical parameters |

| Maximum cable cross-sectional area (mm²) |

630 |

| Maximum insulation outer diameter (mm) |

55.3 |

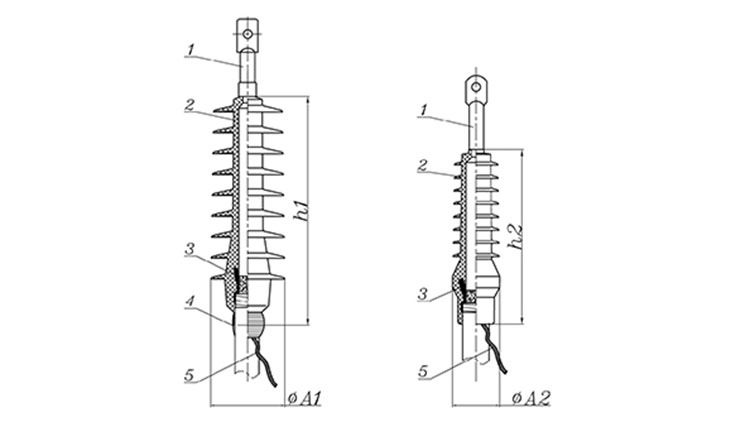

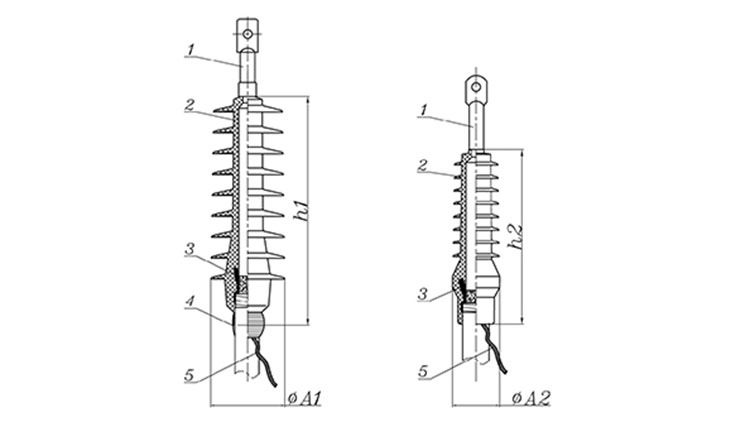

| Main dimensions |

| h1 (mm) |

460-510 |

| h2 (mm) |

335-375 |

| φA1 (mm) |

138-148 |

| φA2 (mm) |

76-94 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

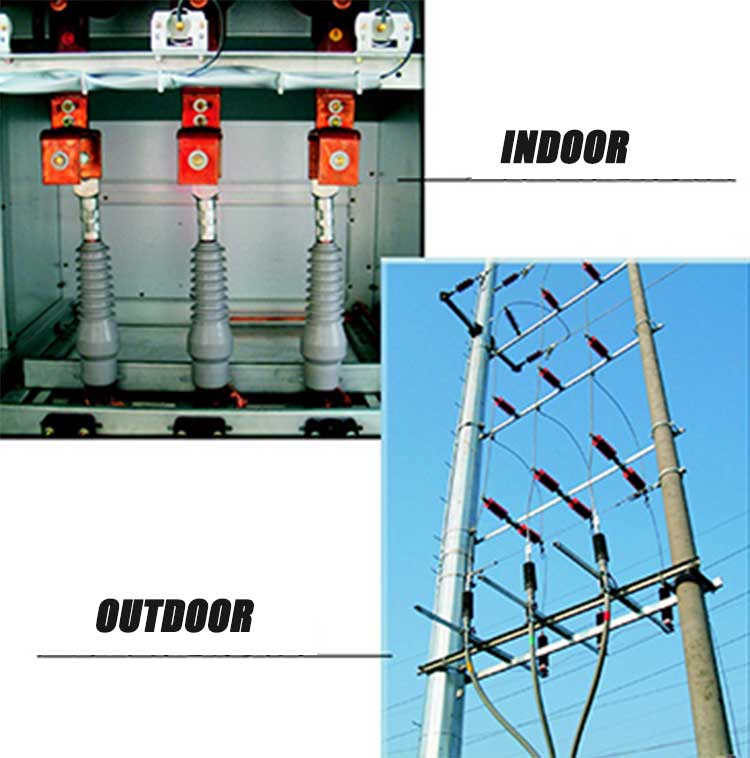

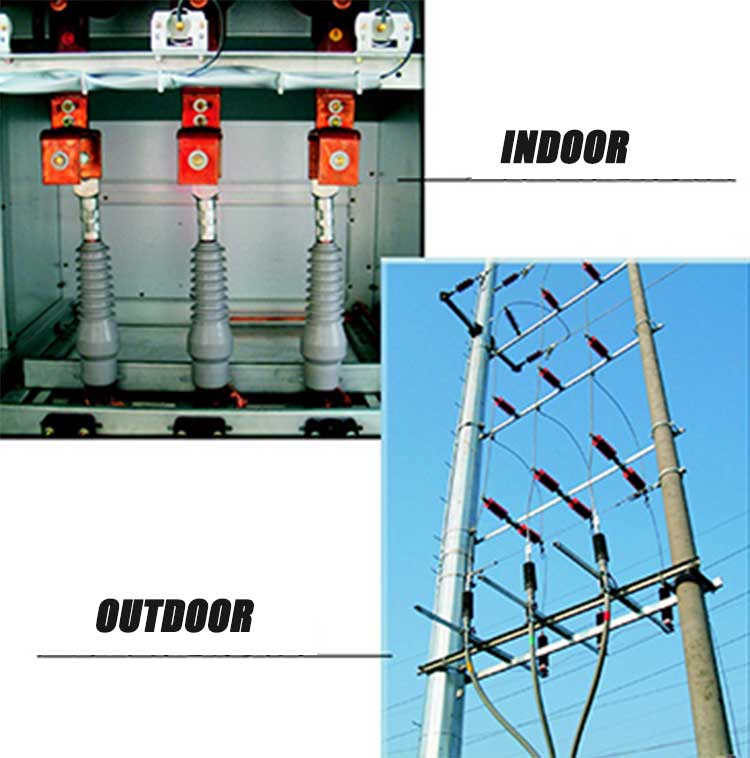

What is Pre-molded Outdoor/Indoor Termination?

High voltage electrical systems need pre-molded outdoor/indoor termination for both indoor and outdoor to give a secure, insulated connection between the power cables and the equipment. This termination uses a pre-molded stress control tube and insulating layer, which have been engineered to end-terminate, maintain the original stress at the cable end, and prevent insulation breakdown with reliable stress relief of optimum electrical characteristics under various operating conditions. Its pre-molded design offers easy on-site installation, with no additional field preparation or heavy tools, resulting in faster setup, with a high standard of insulation quality. Typically these terminations are made from weather-resistant polymeric materials with good resilience and low maintenance over their extended operational lifetimes. High-voltage cable connections are widely used in substations, transformers, switchgear, and power supply systems to increase system reliability by reducing high-voltage cable connection risk factors.

Features

- Stress Cone Structure:

The termination has a stress cone structure included for termination along which electrical stress at cable terminations is effectively managed, yielding a safe, stable, and reliable termination with demonstrated operational success under high voltage applications.

- Liquid Silicone Rubber Construction:

This termination is manufactured with liquid silicone rubber and provides a seal over the insulation maintains the consistent contact pressure and improves the electrical performance through durable material properties.

- Customizable Trifurcation Area Materials:

This termination is equipped with configurable materials in the trifurcation region that can be tailored to specific user requirements to aid in the flexibility of adaptation to several installation needs.

- Flexible Storage Requirements:

Its integrity and effectiveness are intended to be maintained as an unbounded, undesired termination that should be stored without constraints on storage duration.

- Suitable for Highly Polluted Environments:

The outdoor version is designed for reliable use in areas classed as Grade IV pollution zones and exhibits resilience and performance in harsh environmental conditions.

- Specially Designed Outdoor Termination:

It is engineered for wider use in outdoor termination to enhance resistance to moisture while providing enhanced moisture protection within the weather range and delivering dependable operation in wet conditions.

Main Components

- Cable Lug:

T2 copper cable lug is made from T2 copper, which is a combination of copper and tin, which can provide a reliable connection between the cable conductor and the terminal equipment, facilitating the conduction of electrical and a secure mechanical connection.

- Termination Head:

The Pre-molded Outdoor/Indoor Termination, made of liquid silicone rubber and featuring high durability and outstanding insulation properties, isolates the cable end and helps to keep performance stable.

- Stress Cone:

The stress cone consists of a semi-conductive adhesive material for control and even electrical stress distribution at the cable end, eliminating the risk of electrical discharge and improving safety and reliability.

- Self-Amalgamating Insulation Tape:

A strong and cohesive layer of insulation around the cable, this tape is made out of butyl rubber, providing a firm seal and keeping it from allowing dielectric breakdown or moisture ingress over time.

- Grounding Braid:

The grounding braid of T2 copper stands also helps to ensure a safe ground connection by diverting excess current away from the cable.

- Trifurcating Sleeve:

The trifurcating sleeve separating, isolating, and insulating the three phases for multiphase cables, manufactured from liquid silicone rubber, is designed to separate and insulate the three phases and to minimize the chance of short circuits between the phases.

Certificate

Factory

Hot Tags: Pre-molded Outdoor/Indoor Termination, Cable Accessories, Thailand, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage