Specification

| Type of Insulator |

FZS-1.5/9 |

| Specified Voltage |

1.5 kV |

| Specified Mechanical Tensile Failing Load |

50 kN |

| Specified Mechanical Bending Load |

13 kN |

| Section Length |

110 mm |

| Min Insulation Distance |

110 mm |

| Min. Nominal Creepage Distance |

250 mm |

| Lightning Impulse Withstand Voltage(Peak Value) |

125 kV |

| Power Frequency Withstand Voltage Test- Wet |

30 kV |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

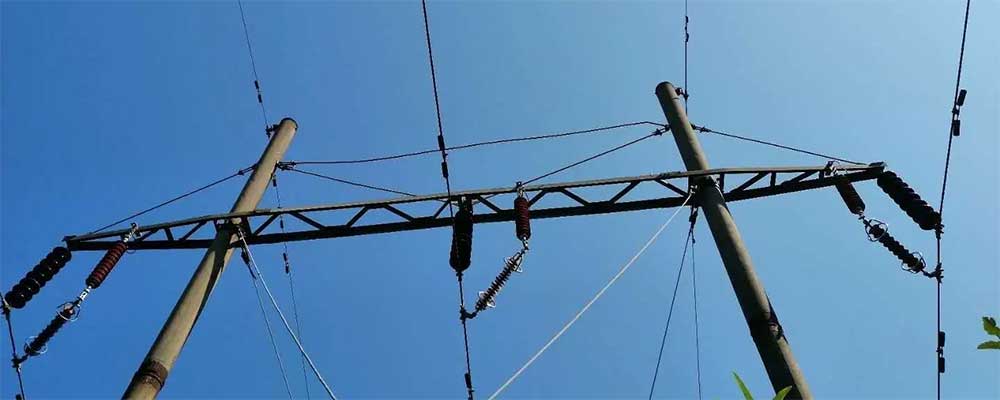

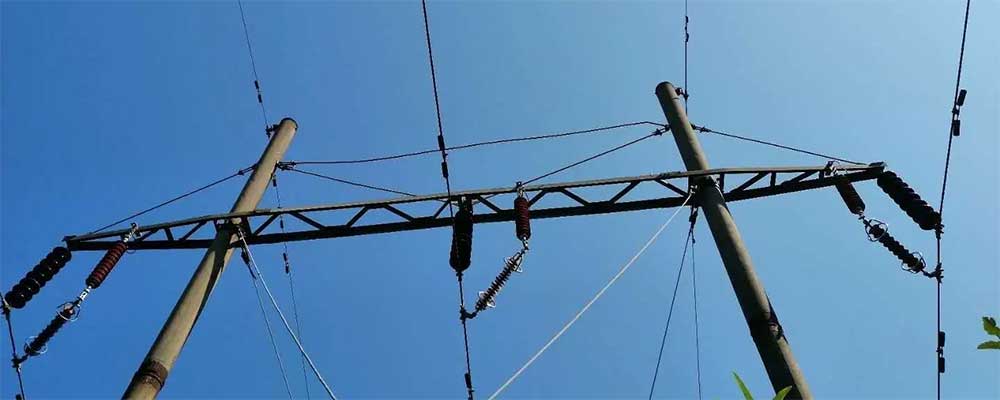

What is the Rigidity Suspension Insulator?

Rigidity Suspension Insulator is a subcategory of high-performance composite electric power insulators, applicable to High-voltage transmission conductors. It incorporates the elements of suspension and rigidity providing better mechanical support and electrical isolation than the standard suspension insulators in some applications. This insulator normally consists of a composite core usually fiberglass-reinforced resin and a silicone rubber covering which offers excellent hydrophobic characteristics to minimize the probability of contamination which results in highly dangerous electrical discharges. This insulator is most appropriate for areas with a more mechanical load such as areas with higher wind velocity, icing conditions, or seismic zones. The solid physical build-up of the structure is designed to keep the conductors firmly in place; the aim is to avoid any lateral movement along the cables as this could be dangerous leading to mechanical failure or electrical faults. Having hardness and at the same time being able to suspend on the transmission line this particular insulator will be efficient in handling dynamic loads on conductors including conductor movement and forces which act on it due to its surrounding environment.

Features

- Rigidity combined with flexibility:

Unlike the traditional suspension insulators which mainly offer flexibility in electrical installations, this suspension insulator comes with a blend of rigidity and suspension that offers stability as well as allows free physical movement to counter checked mechanical forces.

- Superior mechanical strength:

It is intended deliberately for bearing increased mechanical loads which in turn makes it suitable for installation in regions of complex climatic conditions like wind regions or where the conductor experiences high tension.

- Enhanced vibration control:

Its rigid structure helps better control conductor vibrations, reducing the likelihood of oscillations and minimizing the risk of mechanical fatigue in transmission lines.

- Improved load distribution:

The design effectively distributes vertical and horizontal loads, reducing stress points on the transmission line and enhancing the overall stability of the system.

- Compact and lightweight design:

Compared with other forms of insulators, it is more compact and lighter in weight; making transportation, as well as installation in areas that may be hard to reach, achievable.

Cost Analysis

This composite suspension insulator may to some extent lead to higher initial outlay costs because of superior materials, as well as complexity in design that makes it more costly relative to other products such as porcelain or glass used in the industry. But, it is found that it requires a higher initial investment in the technology but this is offset by the long-term benefits. It increases the insulator’s useful life and ability to withstand environmental stresses which in turn decreases the amount of maintenance and replacement required thus minimizing the overall upkeep expenses. Also, this feature makes it easier to install since it would not require a complicated procedure thus may lead to reducing labor costs. The increased cost of using rigid suspension insulators can be justified by the increase in the reliability and service life of the insulators, hence the product is economical in the long run in the application of a high-voltage transmission line.

Application

- Mountain transmission lines:

Often deployed in locations with hilly landscapes, line stability is an important factor in reducing conductor oscillations and providing adequate control of mechanics loads resulting from changes in altitude.

- High wind areas:

Used in the regions where wind velocity is high to support the conductor’s presence, and minimize its movement that may lead to mechanical destruction or electrical breakdown owing to vibration.

- Snow and ice environment:

Placed in places that are characterized by severe levels of ice or snow formation, its structure assists in offering the ability to bear extra mechanical loads created due to the formation of ice and snow over its insulation.

- Earthquake zones:

To be employed in regions that are prone to earthquakes to guarantee that the transmission lines do not become unstable or dangerous in the course of the ground shaking; in addition, to boost the total seismic performance of the power system components.

- Coastal or industrial areas:

For the suspension-type insulator that has better functions in anti-corrosion and anti-environmental degradation, when they are installed in areas with polluted environment or severe salt pollution, long service life and less maintenance demand may be obtained.

Certificate

Factory

Hot Tags: Rigidity Suspension Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage