Specification

| Type of Insulator |

FXBW-500/(420/400) |

FXBW-500/(550/530) |

| Specified Voltage |

500 kV |

500 kV |

| Specified Mechanical Tensile Load |

420/400 kN |

550/530 kN |

| Connection Structure Mark |

28 |

32 |

| Section Length |

4450±50 mm |

4450±50 mm |

| Min. Arcing Distance |

4000 mm |

4000 mm |

| Big shed Diameter |

190 mm |

218 mm |

| Diameter of Grading Ring |

350/370 400 mm |

350/370 400 mm |

| Diameter of Grading Ring |

370/400 mm |

370/400 mm |

| Min. nominal Creepage Distance |

14000 mm |

14000 mm |

| Lightning Impulse Withstand Voltage(peak value) |

≥2250 kV |

≥2250 kV |

| Operating Impulse withstand Voltage(Peak) |

≥1240 kV |

≥1240 kV |

| Power Frequency WithstandVoltage Min.Wet(RMS) |

≥740 kV |

≥740 kV |

| Reference Weight |

33 kg |

34 kg |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

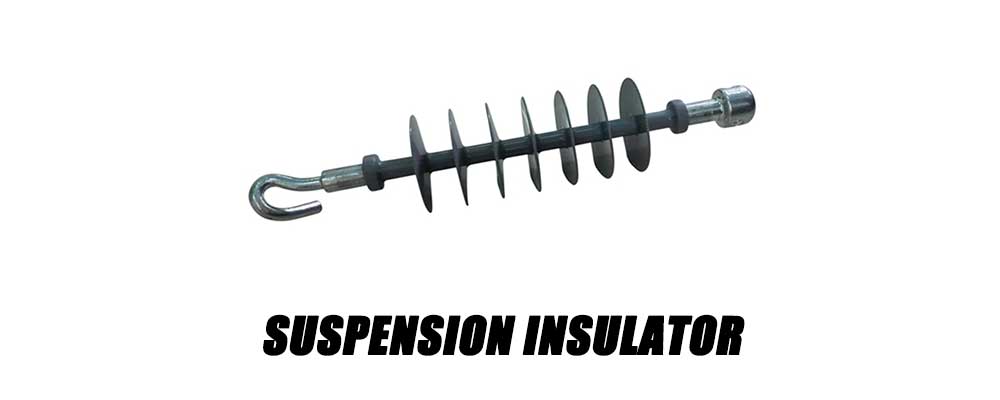

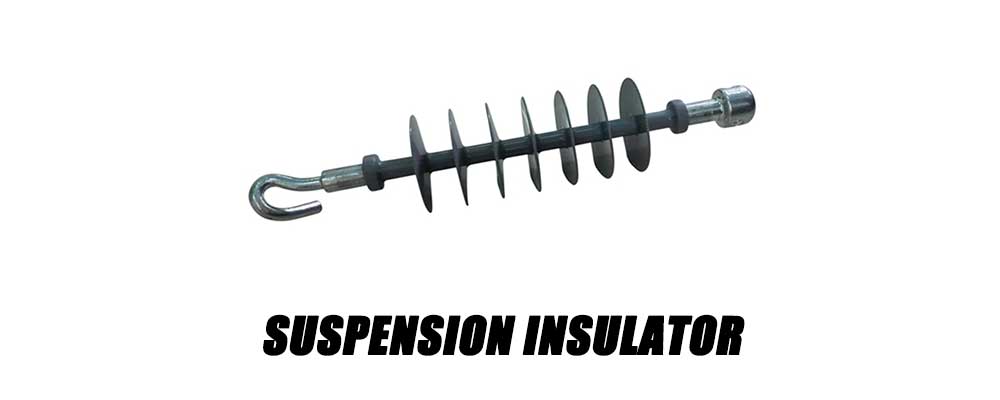

What is the Suspension Insulator?

Suspension insulators are a type of important equipment used in the transmission and distribution of power through the suspension of conductors on utility poles or towers involving electrical insulation and mechanical support. One of its main tasks is to shield live conductors from conducting structures that are grounded, thus reducing the risk of electrical faults and improving the overhead lines’ operating safety. These insulators are generally applied as strings, that is, a number of these units are connected in series to provide the desired level of electrical insulation the number of units used ranges with voltage. It is to a large extent made of composite materials. This ability makes it perfect in areas where line angles are flexible because this manner, the conductor may sway and adjust with various forces, including wind or ice load without affecting the structural stability. They facilitate the handling of mechanical loads permitting fewer line breaks and correspondingly greater dependability of the transmission system. The design also ensures even distribution of mechanical loads along the string – a factor that is very essential in preventing individual unit failure and thus ensuring longevity in performance.

Features

- Lightweight design

The composite suspension insulator is made of composite materials such as silicone rubber which is much lighter than porcelain or glass insulators. This lightweight property reduces the amount of load borne by towers and other structures, enhances the ease of handling and installation of property, and ultimately decreases transport costs.

- Mechanical strength and flexibility were other parameters observed with high values.

It has a higher mechanical strength and more flexibility as compared to the initial phase. Because of this flexible composite casing, the structure can accommodate and diffuse mechanical loads, including wind, ice, or seismic forces more effectively. This makes them function better in uncertain situations.

- Very good water repellency, as well as resistance to pollution.

It also uses silicone rubber which has good anti-aging features and properties of low dielectric constant, and high hydrophobicity to reduce the chance of a conductive water film formation on the insulator surface. This feature provides excellent performance in polluted environments by minimizing leakage current and flashover risks, a significant advantage over traditional materials.

- Highly resistant to damage and breakage

It is not susceptible to damage and breakage. The composite material has a strong resistance to impact and cracking, making these insulators a safer and more reliable choice, especially in areas prone to damage.

- Enhanced UV and Weathering Resistance

It can withstand UV radiation, extreme temperatures, and other harsh environmental conditions without degradation. This weathering resistance extends their service life and maintains their insulating properties over time, providing better durability than traditional insulators.

Installation Notes

- Check insulators and accessories

Suspension-type insulators need to check all insulators and accessories for damage or defects before installation to ensure compliance with technical specifications.

- Proper handling and use of special tools

Avoid sharp objects and heavy pressure during handling, and use special tools for installation to prevent damage to the silicone rubber surface.

- Control installation torque

This is especially so when tightening the screws used to fix the hardware where the torque applicable should be that recommended by the manufacturer since over-tightening or over-loosening can cause considerable damage.

- Keep the surface of the insulator clean

Ensure that the surfaces of the insulators to be installed do not have any formation of contaminants that may make attach or impair its function.

- Prevent excessive bending and twisting

Nevertheless, it is important not to twine or bend the insulator beyond a certain degree during its installation as it may hurt the internal core material.

- Check and maintain sag of fasteners

Check the firmness of fasteners after installation, and ensure that the sag of the conductors and insulators is appropriate to prevent excessive mechanical stress.

Application

- High-Voltage Transmission Lines

It is most commonly used in high-voltage transmission lines because of its electrical and mechanical properties. It helps prevent flashovers and can also withstand severe weather conditions hence making it fit for both rural and urban power grids.

- Coastal and Industrial Areas

In coastal and industrial areas, It is preferred compared to the others because of the better resistance to pollution and salt content. This is because surfaces, that have hydrophobic characteristics like silicone rubber do not allow dust, salting, or chemical pollutants to compromise their functional performance.

- Seismic Zones

Thus this insulator can be used in the region where there are frequent seismic activities because it possesses flexibility as well as mechanical stress resistance. In earthquakes, they help utilities transmit electricity through power pylons with reduced chances of cracking or breaking to improve the reliability of service delivery.

- High Altitude Installations

In high altitudes, it is used since it is lighter than glass or porcelain and hence is easy to handle. According to organismal performance indicators, they are less sensitive to reduced temperatures and, thus are ideal for extreme climates.

- Urban Power Distribution

It is also used in urban power distribution systems where matters concerning space and weight are of great concern. This makes them very suitable for city use due to the lightweight and non-initiative nature they have for vandals.

- Renewable Energy Projects

These dead-end suspension insulators are employed in renewable power generation including wind and solar manufacturing which require dependable insulation for electrical cables that interconnect renewable generating sources with the power grid. One of the most obvious benefits is that they are extremely wear-resistant and can easily be adapted to the existing environmental conditions in these uses.

Exhibition

Certificate

Factory

Hot Tags: Suspension Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage