Wishpower has been specializing in composite insulators for more than 20 years. We always adhere to the same quality. We provide our professional products and services to customers in different industries in different countries around the world. Please use this website or directly contact info@wishpower.net to obtain the most suitable products and solutions for you.

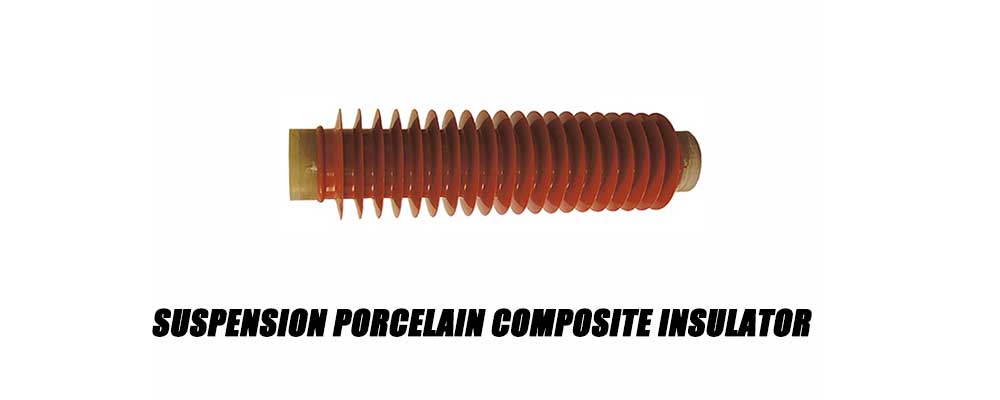

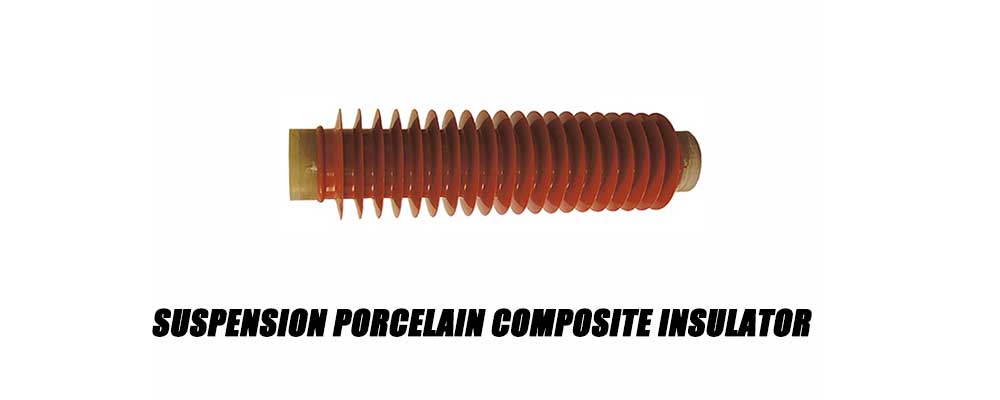

What is the Suspension Porcelain Composite Insulator?

Suspension Porcelain Composite Insulator is one of the newest insulators for transmission lines having the benefits of porcelain and Composite insulators. This insulator is constructed with an outermost core of porcelain – a ceramic material that offers great mechanical strength, and resistance to wear, moisture, and temperature variations. Outside the porcelain core is a composite cover which is also made from polymer substances that make the insulator more protective and efficient in its operations. Compared to the existing all-porcelain type of insulators, the composite housing enhances the insulator’s ability to stand pollution, has lower mass, and better resist water absorption. By incorporating the features of porcelain and composite materials, the Insulator is particularly suitable for high-voltage transmission lines where dependability and performance stability, in the long run, become paramount. It has the advantage of giving better electrical insulation, mechanical support, and low maintenance than other Insulators hence used most in areas with environmental challenges.

Advantages Of Porcelain core (instead of FRP core rod) composite insulator

- Mechanical Strength:

Porcelain subsistent in the porcelain suspension insulator has enhanced mechanical steadiness in comparison to other types of subsist that give better tolerance to the physical force of compression, tension, and bending. Due to this, such systems are well suited to applications that demand high mechanical loads.

- Durability:

It has very high durability and it can easily last for long periods it can even endure extreme weather factors such as UV radiation, temperature, and pollutants. This often leads to increased service life, which is longer as compared to FPR cores.

- Thermal Stability:

It has good thermal stability, which makes it withstand its properties without undergoing any negative changes with the variation of temperature. This is especially useful in areas with drastic temperature changes say between day and night as well as between seasons.

- Electrical Insulation:

The dielectric properties are even better, as the material can insulate voltages much better than other materials, thus decreasing the possibilities of electrical breakdown, particularly in those circuits that use high voltage.

- Fire Resistance:

It is intrinsically fire retardant thus minimizing fire risks in instances of electrical malfunctions. This is a very good safety aspect as compared to the FPR core which may be prone to fire.

Application

- High-Voltage Transmission Lines:

Porcelain core suspension-type insulator is used in high-voltage transmission lines, especially in areas with high degrees of pollution or extreme climate conditions. Thanks to their high mechanical integrity and excellent electrical resistivity they effectively contribute to delivering the electrical energy over large distances.

- Railway Electrification Systems:

These insulators are employed in railway electrification services for overhead contact line applications. The porcelain core ensures sufficient mechanical strength to support loads from the contact wires whereas the composite body shields it against environmental degradations like moisture and pollution.

- Substation Equipment:

In electrical substations, for instance, they are used in the isolation and mounting of electrical equipment including transformers and circuit breakers. Both materials have greater thermal stability and fire resistance hence making them ideal for such important roles because safety is important.

- Coastal and Industrial Areas:

They are often installed in coastal and industrial areas where there is a high risk of salt or chemical pollution. The composite housing offers enhanced resistance to contaminants, while the porcelain core maintains mechanical integrity, ensuring long-term performance in these challenging environments.

Cost Analysis

- Initial material cost:

Returning to cost differences between porcelain cores and FPR cores, it is possible to state that for the most part porcelain cores are more expensive in terms of material costs in the initial stage. Porcelain also known as ceramic cores is made of more costly materials and the manufacturing process is relatively more complicated.

- Manufacturing process:

This is because like all ceramics, manufacturing of ceramics entails a firing process which is more energy-intensive and time-consuming when making porcelain cores. On the other hand, cores of FPR can be made quicker consuming less energy in the process, and are cheaper in manufacturing.

- Installation cost:

Porcelain cores are heavier, which results in higher shipping and installation costs. The added weight may require a more rigid support structure and additional labor, which further increases the overall installation expense compared to the lighter FPR cores.

- Maintenance and lifespan:

It has been also noted that, even though the porcelain cores are more expensive initially, they have a longer service life and fewer maintenance needs, which may lead to cost savings in the long run. FPR cores may require more frequent inspections and replacements, which may increase maintenance expenses over time.

- Total Cost of Ownership:

Ceramic core composite suspension insulators although more costly than other insulators in initial investment per unit, when compared based on the cost of materials, installation, maintenance, and the useful life of the insulators, can be more economical especially where reliability and long service are important.

Certificate

Factory

Hot Tags: Suspension Porcelain Composite Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage