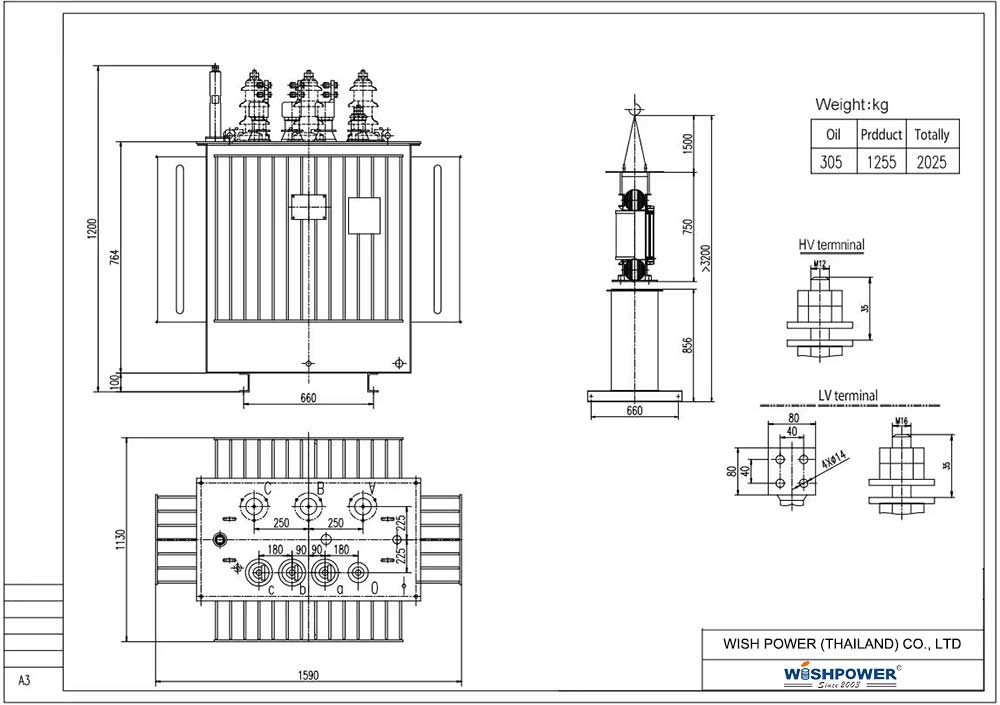

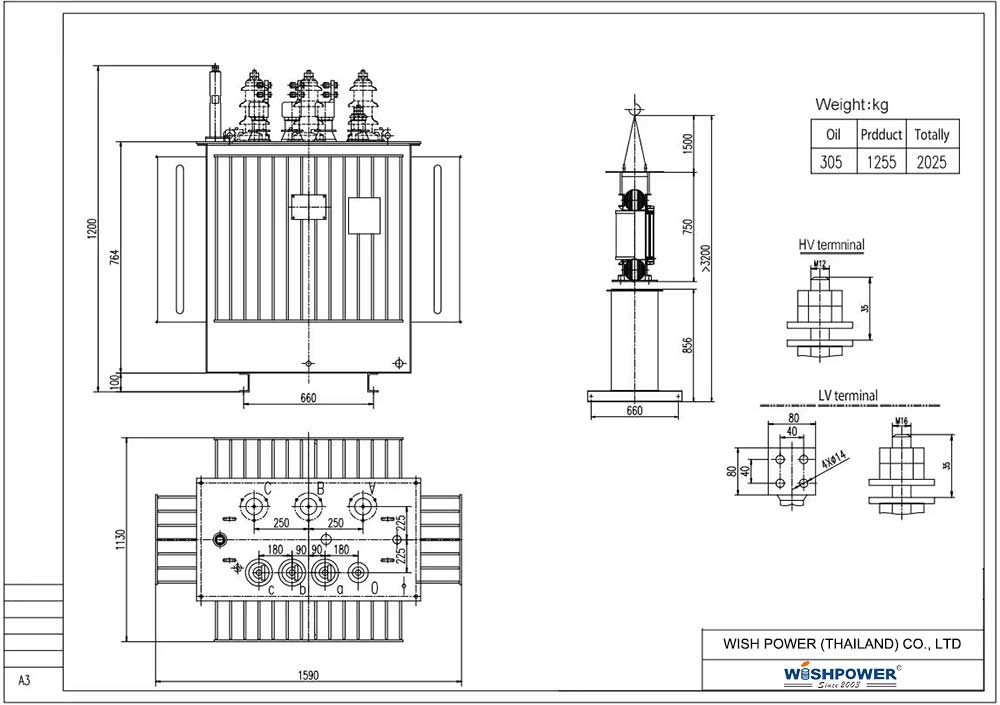

Specification

| Rated Capacity(KVA) |

75 |

112.5 |

150 |

225 |

300 |

500 |

750 |

1000 |

1500 |

2000 |

2500 |

| HV/v |

4160 7200 12000 12470 13200 13800 19920 24940 34500 |

| LV/v |

110 220 230 400 480 |

| Connection Symbol |

Delta-Wye Dyn1 Ynyn0 |

| Standard |

IEEE ANSI DOE |

| Short-circuit Impedance(%) |

4%-7% |

| Efficiency (%) |

99.02 |

99.12 |

99.15 |

99.24 |

99.27 |

99.36 |

99.4 |

99.43 |

99.49 |

99.51 |

99.53 |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net

What is the Three Phase Oil Transformer?

The Three Phase Oil Transformer is an important electrical device that is used in three-phase power systems for increasing or decreasing voltage. It is an electrical energy transfer device, which operates by electromagnetic induction with its three windings, one for each phase, a primary with a set of coils, and a set of coils, with a secondary. This transformer’s notable feature is insulating oil, usually mineral oil, which serves two main purposes: When it is cooled and insulated with electricity. Cooling is important as heat from its operation has to be dissipated, so that thermal performance remains within limits, and overheating is avoided. The oil circulates, taking up heat in the windings and core, and is then cooled either naturally or forced by a fan or radiator. The oil is an insulator and acts to reduce discharges by reducing the risk of short circuits and by improving the dielectric strength. It (the transformer) is designed around an iron core, usually of laminated sheets of silicon steel to minimize the losses of energy due to eddy currents and hysteresis. The windings of copper or aluminum conductors are surrounded by oil and then surround this core. The three-phase design features balanced and efficient transmission of power and these transformers make ideal applications for high-capacity power distribution in the industrial, commercial, and utility industries.

How does an oil transformer work?

The oil transformer transfers electrical energy from one circuit to another through the process of electromagnetic induction and provides cooling and insulation by using oil. A transformer’s function is based on the magnetic core and the two main sets of wire known as a primary (or primary winding) and a secondary (or secondary winding). When alternating current passes through the primary winding its magnetic field will induce a voltage into the secondary winding, both transfers of power. The transformer may step up or down voltage depending upon the need of electrical system design. This insulating oil inside the transformer can either cool and prevent electrical failures or, when it overheats, sparks can develop, causing the transformer to explode. The heat generated inside is absorbed and dissipates this heat. Additionally, an electrical insulator fills the space around the windings to prevent discharges or short circuits from high voltage.

What is the difference between the 3 single-phase transformer and 3-phase transformer?

Using three single-phase transformers, each unit by itself processes one phase of the power system, resulting in slightly higher energy losses and reduced efficiency in comparison to the dedicated three-phase oil-filled transformer. Whereas, a three-phase transformer is devised to make provisions for all three phases within the single unit with the same magnetic core and tank. The common magnetic circuit also enables higher efficiency energy transfer and fewer losses. Moreover, the compacted three-phase transformer occupies less area and is more advantageous for use in installations where the space constraints are high. As both are generally simpler to maintain and install, they involve just one unit as opposed to three separate ones. Conversely, when a fault or failure occurs, replacing or repairing a three-phase transformer may be more involved than can be achieved with three separate single-phase units because only the afflicted unit would have to be serviced or replaced.

Is it safe?

The liquid dielectric transformer is thought to be safe as long as they are maintained and operated within design parameters. Safety is maintained by insulating oil as both a coolant and an electrical insulator, to assure against overheating and electrical discharges. It effectively dissipates the heat generated during operation and insulates high-voltage components thereby minimizing the chance of short circuits, electrical failure, or total failure. The safety is largely based on regular maintenance; checking for oil quality and watching for contaminants and deterioration. The insulating and cooling properties of the oil can be reduced if the oil is contaminated with moisture or particles increasing the risk of internal failure, overheating, or even fire. Pressure relief devices and temperature monitoring systems, which are in some sense advanced safety features, are often added to transformers to detect and stop any kinds of problems before they get serious.

Certificate

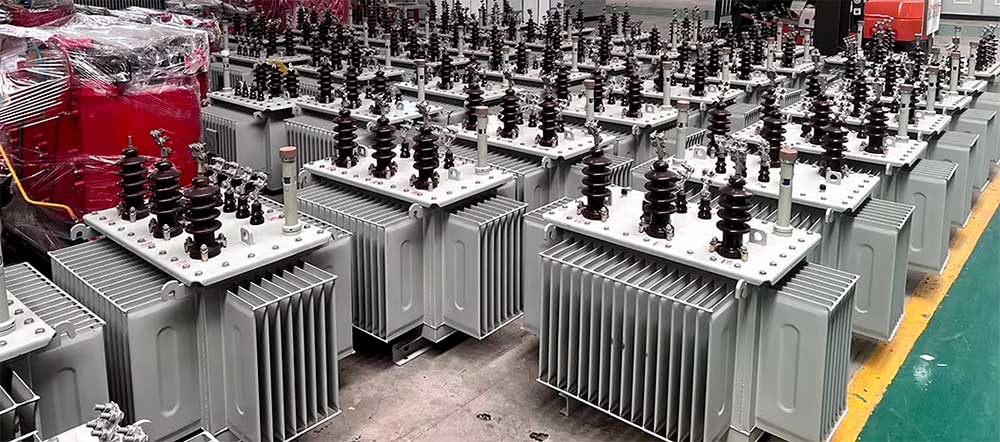

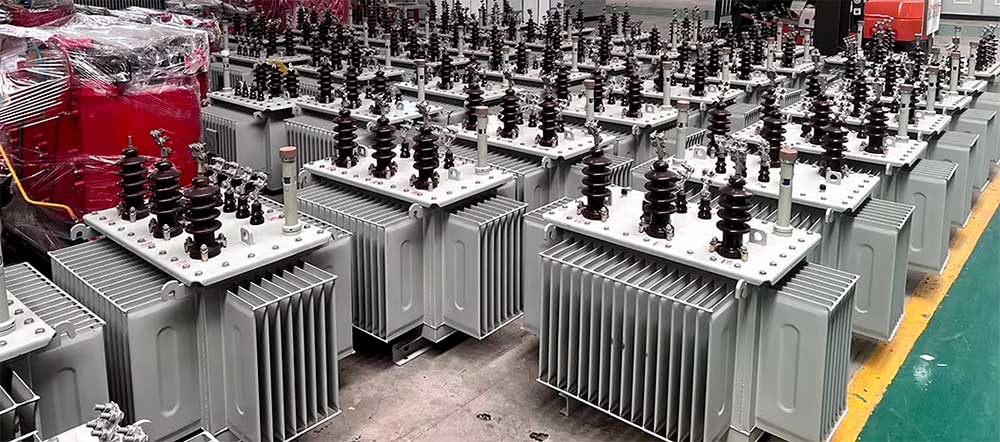

Factory

Hot Tags: Three Phase Oil Transformer, Transformer, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage