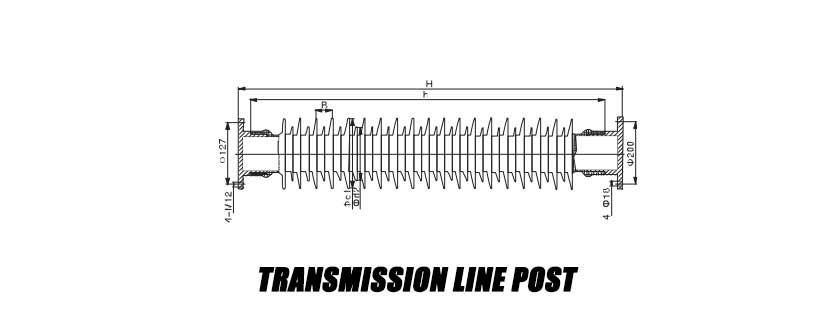

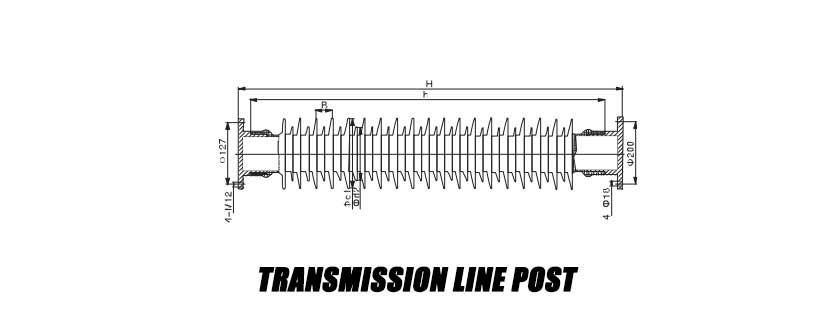

Product Specifications

| Core |

FRP rod |

| Sheds |

High-quality silicone rubber |

| Voltage Rating |

115 / 138 / 230 / 345 / 500 / 765 / 1000 kV |

| Dielectric Strength |

60 kV/mm |

| Creepage Distance |

1200 mm |

| Tensile Strength |

120 kN |

| Compressive Strength |

90 kN |

| Torsional Strength |

70 Nm |

| UV Resistance: |

ASTM G154 |

| Pollution Class |

Heavy |

| Temperature Range |

-40°F to +140°F (-40°C to +60°C) |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

What is the Transmission Line post-insulator?

Transmission line post insulators are a specialized component used in power transmission systems designed to support and isolate live conductors on transmission towers or poles. These insulators are securely mounted on horizontal or vertical structures and are integral to maintaining the stability and safety of transmission lines. Unlike suspension insulators that are suspended from towers, it provides a sturdy upright support that can withstand the mechanical stresses generated by the weight of the conductor and the electrical stresses generated by the high voltage. Wishpower is typically made using materials such as composite polymers that have high dielectric strength and durability in harsh environmental conditions. These are often employed in high-voltage transmission lines where they protect the conductors from the structures they are suspended from by providing electrical insulation to prevent electrical discharge or flashovers. Moreover, it is used in areas with restricted space and where the transmission line is needed to change direction or height to offer mechanical support and electrical insulation.

Market Trends

The line post-insulator market is expected to witness strong growth, driven by the growing global demand for electricity and the need to upgrade aging power infrastructure. Expansion of renewable energy projects such as wind and solar farms is also driving demand as these facilities require extensive transmission networks. In addition, the shift toward smart grids and the need for reliable, high-performance insulators in harsh environments are driving the market. Advancements in composite materials offer better durability and lower maintenance costs, further supporting the positive outlook for the market. This growth is particularly evident in developing regions as electrification and grid expansion are top priorities in these regions.

Features

The composite line post insulator is much lighter than porcelain or glass insulators. This reduces the load on the transmission structure, making installation easier and generally more cost-effective.

- High mechanical strength:

They have excellent mechanical strength, allowing them to withstand high tensile loads and mechanical stresses without compromising performance.

- Excellent pollution performance:

The hydrophobic properties of the silicone rubber it uses give it better performance in polluted environments. They resist the accumulation of pollutants, reducing the risk of flashover.

- Damage resistance:

It is not prone to breakage due to impact or damage, which improves the reliability of the transmission line.

- Flexible design:

Its core is usually made of glass fiber-reinforced resin. This allows for greater flexibility in design and customization to meet specific application requirements.

- Low maintenance requirements:

It is quite immune to pollution and the unfavorable influences of the environment. Hence, they are cleaner than and require less frequently than other refrigeration systems, thus lowering ongoing operating expenses.

Application

- Compact Transmission Lines:

It is ideal for compact transmission line designs where space is limited. Their lightweight and versatile design allows for tighter spacing between towers without compromising electrical clearance or safety.

- Wind and Ice-Prone Areas:

It is preferred wherever winds are too strong or where the building is expected to bear the load of ice buildup because of its superior mechanical properties and flexibility. They are capable of withstanding the other mechanical pressures associated with climatic conditions to guarantee positive functionality.

- Urban and Industrial Areas:

These insulators are fit for use in areas that are highly polluted such as the urban and industrial areas. The outer layer of the composite material is hydrophobic, thus the surface does not attract dust and other pollutants, the electrical conductivity remains high and flashover is avoided.

- High-Altitude Installations:

Although it is frequently used especially in highland climatic conditions can be severe. They are highly resistant to pollution and can work well in low pressure which makes them suitable for such uses.

- Retrofitting Older Transmission Lines:

It is frequently used in the retrofitting of older transmission lines. Owing to their light structure, they can be easily set up on other structures which would involve little changes such that older frameworks can be given a longer life.

- Coastal and Marine Environments:

This line post-type insulators are particularly used in coastal regions where there is a lot of salt fog and high humidity which cause high rates of corrosion.

Certificate

Factory

Hot Tags: Transmission Line Post Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage