Product Specifications

| Core |

FRP rod |

| Sheds |

High-quality silicone rubber |

| Voltage Rating |

110 / 115 / 138/ 161/ 220 / 230 / 330 / 345 / 400 / 500 / 750 / 765 / 800 / 1000 kV |

| Dielectric Strength |

70 kV/mm |

| Creepage Distance |

1500 mm |

| Tensile Strength |

160 kN |

| Compressive Strength |

100 kN |

| Torsional Strength |

80 Nm |

| UV Resistance: |

ASTM G154 |

| Pollution Class |

Heavy |

| Temperature Range |

-40°F to +158°F (-40°C to +70°C) |

The table above is just one of our product parameters. If you want more information, please get in touch with info@wishpower.net or download the file below.

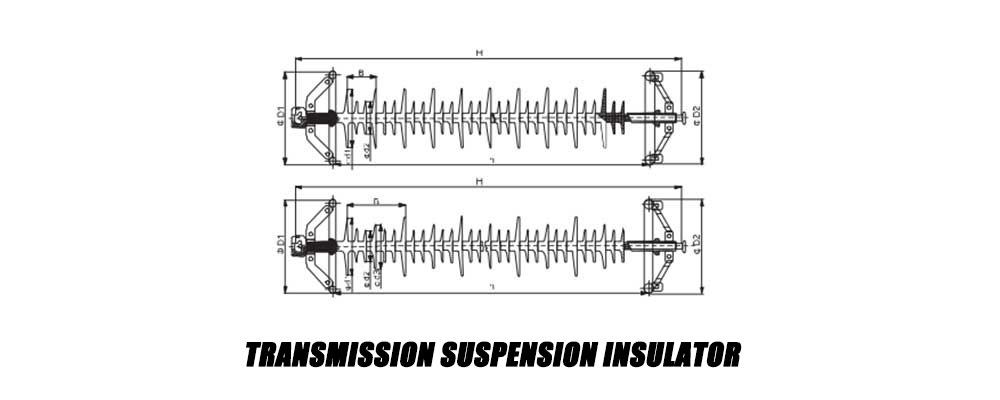

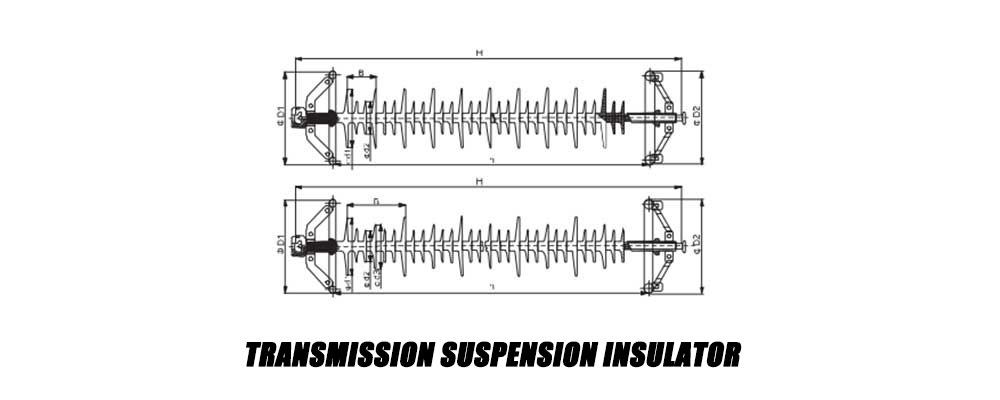

What is Transmission Suspension Insulator?

Transmission Suspension Insulator is an essential accessory of high-voltage power transmission systems. They are applied to hang and at the same time support overhead conductors apart from insulating the conductor from the transmission tower. These insulators are generally of materials like composite polymers which are quite strong mechanically and have very high insulation capabilities. They are normally packed in strings, or series together to cope with the high voltage in transmission lines. Its primary use is to halt the flow of current from the conductor to the grounded tower efficiently and safely to facilitate the long-distance transfer of electricity. They also participate in supporting the mechanical structure of the transmission line; the conductor weight is supported for example due to wind, ice, or pollution. These insulators are employed at different voltage levels of power systems, and they may be of different forms that depend on the voltage level, mechanical loading, and the prevailing environmental conditions of the transmission line.

Production Process

- Core Rod Processing:

The FRP rod, which forms the core of the insulator, is machined to the required length and surface finish. This includes cutting, grinding, and cleaning to ensure the rod meets specifications for strength and durability.

- Fitting Assembly:

Metal end fittings, which are critical to attaching the insulator to the conductor and tower, are assembled onto the core rod. This process typically involves crimping or swaging to secure the fittings firmly in place.

- Vulcanization:

FRP rod is surrounded by silicone rubber and it provides the shell and the skirt of the insulator. The rubber is applied depending on the need of the application either through injection molding or compression molding to ensure uniform thickness and good adhesion to the core rod. The molded rubber is subjected to vulcanization which is a process that increases the rubber’s flexibility, durability, and ability to resist the effects of the environment.

- Quality Inspection:

Every single transmission insulator undergoes a series of tests of electrical, mechanical, and environmental types. Some of the tests may be tensile strength tests, electrical insulation tests, and accelerated tests under environmental conditions.

- Packaging and Distribution:

The insulators are tested for quality and then packed to avoid damages that may occur during transportation, after that they are disbursed among customers and used to reinforce electricity’s transmission system.

Market Trends

Transmission line insulators have enhanced market demand triggered by the high global demographic demand for electricity, more so with the development of renewable energy, and the need for high-voltage transmission. These insulators are used mainly due to their light weight, strength, and nontoxic nature to the environment. Their performance has also been enhanced courtesy of technology making them a worthy rival to traditional insulators. Also, an increment in demand is propelled by the adoption of smart grid technologies and emerging markets for components that form the new generation of electricity networks.

Application

- Overhead Power Lines:

It is used in overhead power lines as a supporter and an insulator of the conductors. These are mounted on the crossarms of the transmission towers and they hold the live conductors so that an electric current cannot pass to the tower or the ground.

- High-Voltage Transmission Lines:

On transmission lines, such as high voltage, these insulators are essential in providing the required electrical space between the energized conductors and the tower. They aid in avoiding flashovers and the subsequent flow of electricity across great distances safely.

- Substation Busbars:

It is applied in substations to provide backup for busbars, which are steel bars that transfer power to different circuits in a substation. They afford the required degree of insulation and they mechanically support the busbars.

- Railway Electrification Systems:

These insulators are also applied in railway electrification structures to provide both support and electrical insulation for the overhead wires that feed electric power to the trains. They see to it that the wires are properly suspended away from the tracks and from reaching the train as well as other structures.

- Transmission Tower Connections:

This composite insulator is used where the transmission line is to be joined to the towers. They bear the load of the conductors and also afford the necessary electrical insulation to avoid the leakage of currents.

Certificate

Factory

Hot Tags: Transmission Suspension Insulator, Composite Insulator, China, manufacturers, ISO factory, wholesale, KEMA, high quantity, best, price, low to high voltage